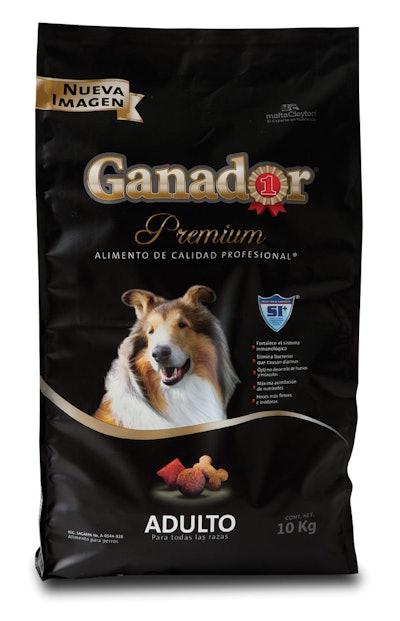

Seems that no matter what the economic condition, many of us want to treat our pets well, be it in the U.S. or elsewhere. Savvy companies recognize this, and are employing packaging as a means of attracting pet owners with attractive on-pack design. In Mexico, for example, Guadalajara-based Malta Texo de Mexico’s Premium Ganador dog food is sold in premade bags produced by Printpack with gorgeous printing and pack shape that add shelf presence.

The package won an FPA Gold Award for Printing Achievement, most appropriate given that the word Ganador translates as “winner” in Spanish. Ganador’s 10-kg sack was completely redesigned with a premium matte finish, employing flexo printing over a rich black background, and improved shape with Printpack’s QuadSeal technology.

“Packaging is everything for the image of our product, and that’s the reason that we work with our partners in research on new materials and improving the quality of design,” says Luis Ramon Roig, with Malta’s marketing team.

The Ganador sack structure for the 10-kg version is a 20-micron (0.8-mil) matte biaxially oriented polypropylene/6-mil low-density polyethlylene that’s reverse-flexo-printed in eight colors. Printpack’s Guadalajara plant does the converting, with the 10- and 20-kg sacks sold as a preformed bag to Malta Texo; a 3.75-kg version is shipped by Printpack as rollstock. The packaging was redesigned early last year, with the first new package delivered in August 2011.

According to Printpack División México, the package provides Ganador with “detailed graphics over a unique and uniform black background, which is hard to obtain with a regular flexo-printing job. One of the primary objectives was to enhance the image of the dog and show a more realistic image of the actual dog food. This package was redesigned to maintain a competitive positioning against one of the leading brands that changed their package to matte finish as well.”

The printing process differs from other dog food sacks in that companies do not usually use matte finish on black backgrounds. As part of the new image, the seals were reinforced with four side gussets to make the package more stable on the shelf, whether displayed horizontally or vertically.

Printpack says the physical material limitations meant that the matte finish was only applied as a first stage to the two smaller sizes; the 20-kg version is a PE/PE structure because of its higher tear resistance. This size is being tested for a future conversion to the matte finish. The packs are filled via a semi-automatic process and sealed automatically. No changes to the process were required to use this new structure, says Printpack.

Roig says the packaging “helps us to increase sales because the product has a very good presentation on the shelf and gives confidence to the consumer that the product is high quality. We are very happy [with Printpack] because they give us all the support to improve our packaging materials, and because we worked together to develop new projects such as this.”