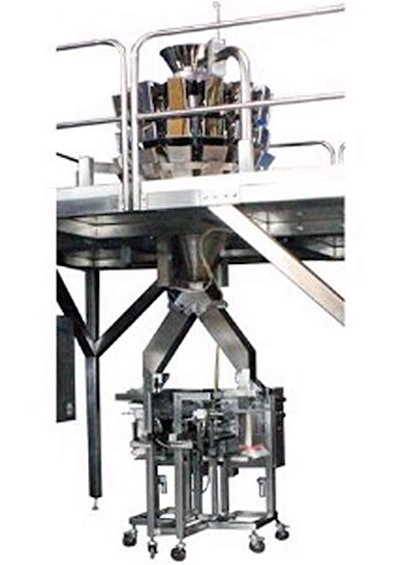

To reach required speeds product travel time between the scale and

bagger has been dramatically reduced. Product spiraling has been

eliminated with individual lane chutes, and a catch box system allows

the product to be double staged—increasing production rates by 40%, and

cycling at more than 60 bags per minute of pita chips in increments of

200 grams. The VS bagger automatically positions a pre-made wicketed

bag, opens it and waits for product. After loading, the VS Bagger

side shifts the bag to the sealer, positions a new bag and repeats the

cycle.