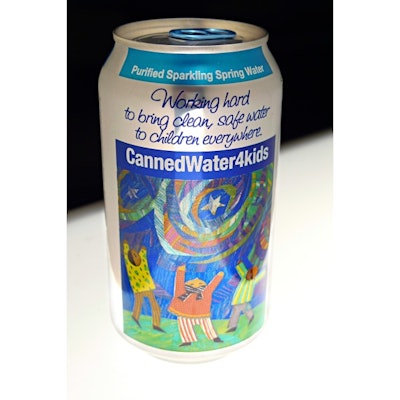

CannedWater4Kids is a North American-based program with global reach

designed to create awareness and fund projects to purify water for

children in developing nations. Coinciding with World Water Week March

22 – 28 and this year’s 50th anniversary of the first aluminum beverage

can, CannedWater4Kids launched spring water in cans from Crown Cork

& Seal’s La Crosse, WI, facility,

offset-printed in six colors to provide a festive appearance. Ink is

supplied by INX Intl.

Printing is done directly on can bodies on a Stolle Machinery Rutherford decorator, at 2,000-can/min speeds.

Printed can bodies are then shipped to Cold Spring Brewery, Cold

Spring, MN, where the sparkling spring water comes from a 300-year-old

underground glacier. Cold Spring, another corporate partner involved in

the program, fills water into the printed can bodies, then seams on a

202-dia aluminum lid to complete the two-piece can.

Cans are available in 12- and 24-count packs at

www.cannedwater4kids.org. Site visitors may order water at the site and

donate directly to the program to get fresh water to children in need.

Out of every dollar collected for the program, 95 cents will go toward

organizations and special projects that bring clean water to people in

need.

Greg Stromberg, INX international director of sales, national

accounts-Metal Deco, developed the idea for CannedWater4Kids after

hearing a speaker at the 2008 Canmaker Summit talk about how developing

nations seldom have packaging to keep food and drinks fresh,

contributing to a World Health Organization claim that one child dies

every eight seconds from drinking unsafe water. That led Stromberg

(shown in the photo) to found the not-for-profit 501c3 CannedWater4Kids

program.

Discussions are underway with several major retailers to sell

CannedWater4Kids through outlets nationwide, with plans to gain

additional corporate support and partnerships with colleges and

universities.

“There is a tremendous global need for the quality of water we take for

granted,” says Stromberg. “Our mission is to find and help fund

programs that are making a real difference for children and are doing so

efficiently and effectively. By offering real value with our pure

sparkling water, we think consumers will join in supporting the

CannedWater4Kids program to help make a real difference, too.”