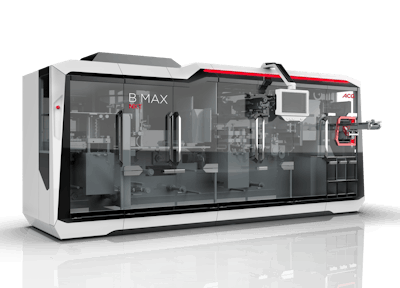

ACG Group, a supplier of end-to-end manufacturing systems for the pharmaceutical industry, has introduced a comprehensive portfolio of next-generation production, packaging, and inspection machinery. Comprising equipment systems from two of its four business units, ACG Engineering and ACG Inspection, the NXT Series is designed to comprise future-ready machines featuring the company’s USER approach meant to improve operator experiences. New machines include Protab 300 NXT, Protab 700 NXT, BMax NXT, KartonX NXT, Verishield CS18 NXT.

USER is an acronym for UltraHMI, StealthDesign, ExploreAR and RevealiOT, Combined, the elevated elements are designed to bring changes to a significant portfolio of ACG machinery including tablet presses, blister and carton packing equipment, and serialization units for Track and Trace applications. The result should be a sizable step forward in all facets of the production experience, according to the company:

- UltraHMI: To align with the continued push for increasingly automated manufacturing systems, ACG’s HMI system is made to provide seamless control of high-precision, contamination-free machines requiring minimal human-machine interaction. Highlights should include a simplified operator experience, better data visualization, decision-centric dashboard, and IIoT connectivity.

- StealthDesign: Machines have a smooth, flowing style, which should exemplify versatility, maneuverability, and increased output at a smaller footprint.

- ExploreAR: Made to be smarter, more secure, and faster, ACG’s Augmented Reality systems are designed to be efficient. ExploreAR should reduces production downtime, identify and resolve maintenance issues more quickly, and keep manufacturing moving at a better pace. Highlights should include real-time monitoring, remote diagnosis and proactive service support, proactive maintenance, and more realistic operator training.

- RevealiOT: ACG’s IIoT platform is meant to enable intermachine connectivity and smart manufacturing processes via easy-to-read dashboards for detailing difficult-to-measure KPIs. Digestible data should provide actionable metrics, a quantum leap in transparency leading to predictive maintenance, improved product quality, and maximized overall equipment effectiveness (OEE). The information is also made to allow for “Golden Batch” repeatability and improved production schedules to enhance machine efficiency while reducing line downtime.