This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

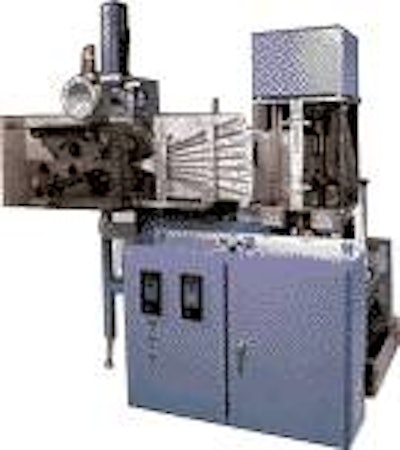

The benefits include an unwind table with an electronic regenerative drive system for precision paper tension control. The ribbon folder makes linear folds with the least amount of paper drag. Maintaining a light tension reduces paper break. It also features air tuck which allows high speed and low maintenance cross folding with no moving parts. GGA’s Napkin Machine is less sensitive to static because the napkins are held more rigid keeping the static from taking control during cutting and folding.

• Elevator Hydraulic providing easy dependable paper roll lift

• Unwind Table Regenerative Drive for reduced paper break even from hard to run rolls

• Heavy Duty Embosser Frame And Bearings give quiet operation and long life

• Removable Stainless Printer Ink Wells for easy clean up

• Light Tension Modular Ribbon Folder low paper drag, reduces paper break and easy changeover

• Inches Nip And Knife Shafts for long, trouble-free, service

• Built-In Knife Adjustment Wedges for easy knife adjustment without disassembly or shims

• Nip And Knife Tractor Rings prevent snap back jams

• Knife And Anvil Anti-Static Mating Rings reduces the static problem

• Air Tucking allows high speed low maintenance cross folding

with no moving parts

• Lift Up Outfeed

opens for easy access for cleaning and maintenance

• Cantilevered Outfeed Rolls

for fast change without disassembly

• Electronic Length Adjustment

for fast change on the fly

The elevator is hydraulic providing a steady dependable lift without the possibility of dropping the roll even if the electrical or pneumatic power is lost. It allows virtually any employee to place the paper roll in position with the utmost safety.

The unwind table has an electronic regenerative drive system. This system provides closed loop information feedback of the paper tension to keep it just right for the particular paper you choose to run. The paper feeds into the embosser via the newly improved dancer system which controls the paper tension with feedback to the regenerative drive of the unwind table. This reduces paper break even from hard to run rolls and keeps you in production.

The embosser is an engraved steel roll and a compressed paper roll that are carefully run together with a time tested procedure that allows full pattern depth even on start-up. The rugged frame and heavy duty bearings give quiet operation and long life. Another dancer controls the tension on the embosser outfeed.

The one or two color printer has removable stainless ink wells for easy clean up and is easily adjusted for different size napkins. With proper set up and ink viscosity the print will be crisp and bright with full depth of color.

The ribbon folder is designed to make linear folds with the least amount of paper drag, maintaining a light tension and reducing paper break. The modular folder allows easy changeover for different fold widths.

Our Napkin Machine employs a special nip safety feature which allows the rolls to open two inches and shuts the system down if a foreign object enters the rolls. Our system’s durable nip and knife shafts have a diameter of 1.25 inches with heavy duty bearings for long, trouble-free, service. Easy knife adjustment is accomplished with built-in adjustable wedges making disassembly and adding shims unnecessary. Tractor rolls between the nip and knife prevent annoying jams and downtime from paper snap back.

We have also added a major improvement to the knife and anvil cutting rolls for anti-static control through the cutting process. The rolls have mating rings which cause the napkin to cup slightly as it is delivered into the cross fold. The cupped napkin is more rigid which keeps the static from taking control as the knife cuts and releases it. This greatly reduces the static problem.

The GGA Napkin Machine also features air tuck which allows high speed and low maintenance cross folding with no moving parts. Lift up outfeed opens for easy access for cleaning and maintenance. Our air tuck changeover features simple o-ring positioning on cantilevered outfeed rolls for fast change without disassembly.

Electronic length adjustment is an available option for fast change on the fly. Other options include two (2) color printing and two (2) cross fold air tucking. These are quoted as an addition in the price section.