PouchLab: who’s it for?

PouchLab is dedicated to brand owners who need to set standards for their packaging, look to optimize the package size, have to consider down gauging packaging or aim to explore new materials for their products. The lab is also meant for those industry players who need to compare the behavior of different structures, test machinability, double check the performance of their film, develop new sustainable solutions or new re-closable features for flexible packaging. The structure will be a strong asset not just for Volpak customers, but also for film converters, cap, zipper manufacturers, technological centres and raw material suppliers, who could take advantage from the numerous possibilities offered by the lab.

PouchLab: where is it and how it can be used?

The laboratory is located in a special area within Volpak premises; guaranteeing maximum confidentiality and dedicated closed boxes for material storage. The area, hosts a state of the art pouch-forming machine, based on hf/f/s technology, and complete testing equipment, which customers can rent and use at their discretion to analyze their material, make pouches and test the quality of the product, all in a controlled environment, counting also on Volpak’s technical expertise. In fact, the company can further support the users thanks to its long-standing experience in the field of pouch processing and packaging, expressing a unique know-how in such fields as new materials applications and energy saving procedures.

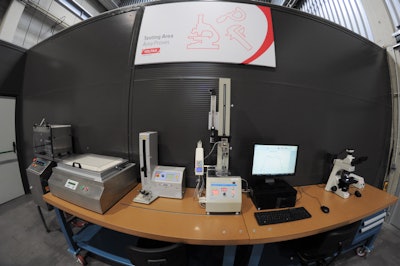

Inside the lab

Pouch forming equipment provided by PouchLab, namely a new generation hf/f/s machine, serves for both flat and stand up pouches. Customers can control and monitor seal temperature, seal pressure and seal time, supervising also the film tension. Finally, it’s possible to measure film stretch in forming area. Other tools provided by this area include an electrostatic charge measure tool, to accurately measure and provide the electrostatic charge of any material, a stress test machine, to obtain clear, accurate and manageable information about pouches stress resistance, a high speed camera for root cause investigation of any issue, and a powerful microscope to analyze the quality of the seals.