It also allows facility managers to plan maintenance more efficiently and reduce labor costs by eliminating manual checks.

Using a proprietary machine learning algorithm, Banner’s condition monitoring solution collects data from the sensor to establish a machine’s vibration baseline and automatically set warning and alarm thresholds.

When a threshold has been exceeded, the wireless node can provide local indication, send the vibration and temperature data to the gateway for long term collection and analysis, and send a text or email alert. The solution serves as a simple “check engine light” for machines; however, data on a variety of vibration characteristics can also be collected over time for more in-depth analysis of machine performance.

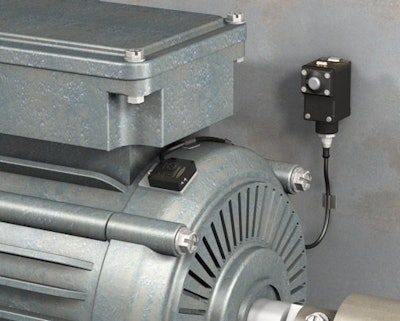

The wireless vibration and temperature sensor is ideal for a variety of machine monitoring applications, including motors, pumps, blowers and many other types of machines throughout a facility.

Manufactured with a zinc alloy housing, Banner’s wireless vibration and temperature sensor provides reliable performance in harsh environmental conditions. The sensors can be easily mounted using a standard bracket, a magnetic bracket, or a two-sided thermal transfer mounting tape to accommodate diverse applications.