“As a leading supplier of food-based packaging technologies, Curwood pays particular attention to existing and emerging consumer trends domestically and globally to support customer growth objectives,” explains David Engen, Curwood Director of Marketing.

“Changing demographics, coupled with shifting economic conditions, have led to trends that support microwave pasteurization technology,” states Engen. “Consumers are demanding higher quality meal solutions that deliver on taste, texture, aroma and aesthetic appeal without the addition of preservatives or additives. MicVac technology provides a nutritious option—without sacrificing convenience—at an extended shelf life of 30-45 days.”

“Proven success in Europe and Asia has established the MicVac solution as the standard in microwave pasteurization,” said Engen.

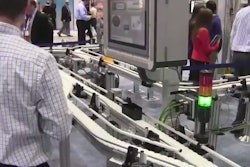

The MicVac method integrates a tray, lidding film and valve technology using a specially-designed MicVac microwave tunnel cooking system. The convenience of cooking raw ingredients and shipping chilled directly to the market changes how food is prepared, delivered and merchandized by brand owners and retailers. The cooking system is also delicate enough to open up product options to traditionally challenging foods like fish, shellfish, pasta and ethnic-oriented meals, offering consumers greater variety and flavor.

Prior to eating, the consumer heats the meal for about three minutes in a microwave, where it cooks under controlled steam pressure. The package whistles when it’s at the correct temperature.

Unlike many heat-and-eat meal formats, the MicVac package goes directly from the shelf to the microwave, with no consumer prep required such as lid piercing or stirring.

The MicVac packaging platform solves a number of critical challenges for ready meal brands, including: extended shelf life without additives; easy and efficient transport and display; simple, safe microwave cooking; the ability to profitably execute ready meal innovations.