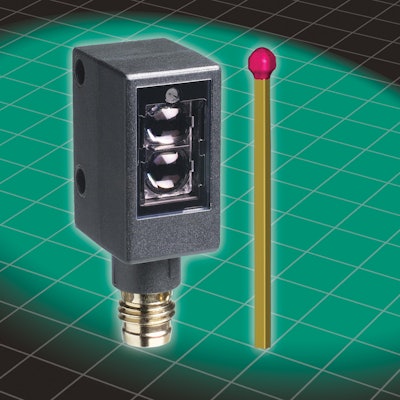

ML4.2 high speed models offer 250 µs response time (said to be twice as fast as standard ML4.2 models) which means less wasted material for converting applications, higher resolution for trigger applications and improved switching precision. ML4.2 dual sensor redundant detection models feature dual light beams from 2 emitter LEDs that reflect light to 2 receivers. This sensor enables transparent or glossy objects that are foil or plastic-wrapped to be much more reliably sensed.

An ML4.2 model with dual sensor redundant detection and independent outputs features dual beams from 2 emitter LEDs that reflect light to 2 receivers, where 2 independent outputs indicate the state of each separate beam. Useful for aligning or guiding translucent paper, plastic and fabric webs, and can also detect a gap between 2 objects. 2 ML4.2 precise sensing models are said to deliver the sharpest sensing distance cut-off and smallest switching hysteresis on the market for background suppression sensors.

A new ML4.2 series retroreflective sensing model with no sensing deadband is used with a corner-cube reflector and is polarized so that shiny objects will not be erroneously seen as the reflector. Well-suited for detecting objects such as solar cell wafers and packaged tubes or cartons where precise and repeatable leading edge detection is necessary.

The ML4.2 series thru-beam sensors deliver maximum signal strength in situations where retroreflective and background suppression models do not have sufficient optical power. Suitable for applications with sensing distances up to at least 8 meters, and in dirtier environments.