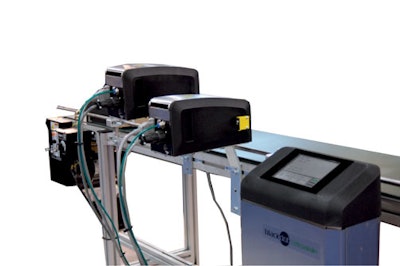

The compact hot-melt delivery system is entirely encased in the imaging module for maximum flexibility, rapid service, and low energy consumption. The coding system combines the benefits of instantly drying hot-melt print technology with the company’s proprietary, stainless-steel piezo printhead to provide high-resolution images up to 2.5 in. high in one- or two-head configurations. The CleanCode™ hot-melt ink puck prints crisp high-resolution codes on porous and nonporous substrates without ink bleed or solvents. Black Dot’s proprietary CodeMaster™ design software allows users to design codes in minutes that can then be stored locally or hosted on Black Dot’s Web site and sent to the coder through multiple interface options, including USB and Ethernet.

Phone: 860/507-2000 www.blackdot.com