To meet upcoming 2017 serialization mandates facing pharmaceutical manufacturers, ESS Technologies, Inc., integrated its Model V30HS High Speed Robotic Case Packer with off-the-shelf serialization equipment to create a compact, fully automated system for aggregating and serializing case contents during the case packing process.

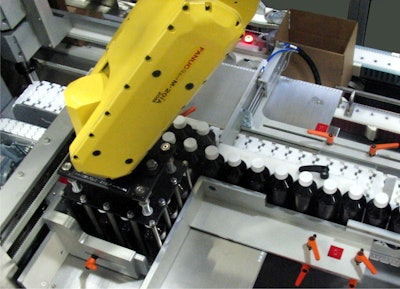

Capable of handling bottles, cartons, bundles and blisters, the V30HS uses a FANUC M-20iA robot for case loading.

Working with Optel Vision, an OEM of serialization systems, ESS integrates the 360° Camera System at the infeed of the V30HS. Bottles labeled with unique ID codes are scanned at a rate of up to 400 bottles/min as they enter the servo collation area. The V30HS automatically forms the correct pack pattern while simultaneously erecting an RSC case and placing it in the loading position.

The FANUC M-20iA robot, equipped with custom, ESS-designed end-of-arm tooling (EOAT) will pick the entire pack pattern of bottles and load it into the case. Layer sheets may be placed to accommodate a two-layer pack pattern. The robot can also be programmed to add medguides or booklets to the case.

Prior to closing the case, an Optel Vision overhead camera verifies that the case is fully loaded before the V30HS seals the case on the top and bottom with standard 2-in. tape. (A glue closure option is also available.) A case checkweigher may also be integrated with the V30HS to verify case weights. Incorrect cases are automatically rejected from the system. For correctly loaded cases, information about the bottle codes is transferred from the serialization PC to an integrated case labeler that prints the required serialization code and applies the case label. A final Optel Vision scanner verifies the printed label before the case exits the system.

ESS works closely with all major OEMs of serialization systems to assure seamless integration with its line of packaging machinery and has installed track-and-trace-ready cartoners, case packers and palletizers in a number of pharmaceutical manufacturing facilities.