This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

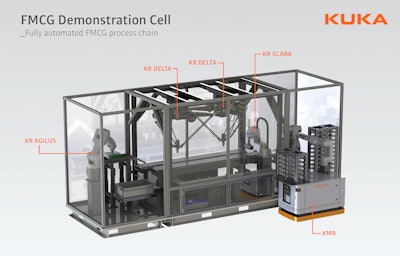

At PACK EXPO 2022, KUKA Robotics showcased its new complete, end-to-end process automation multi-robot cell for the Fast Moving Consumer Goods (FMCG) industry. The demonstration featured completely integrated automation – including robots, mobile platforms, advanced vision and software.

Designed to simulate a real production environment and automation solutions for each step - moving material from receiving and sorting to packing and distribution - the cell include KUKA’s new KR 3 DELTA Hygienic robot, KR 6 SCARA and KR 6 AGILUS robots, a KMR iiwa autonomous mobile platform and advanced vision software, KUKA.VisionTech.

The KR 3 DELTA hygienic robot provides outstanding performance and value for pick-and-place applications for the food, packaging, electronics and pharmaceutical industries. The KR 3 DELTA combines precise grip, corrosion resistance and minimal maintenance requirements to excel in sensitive high-speed production applications. This ceiling-mounted robot offers a reach of 1200 mm, a maximum payload capacity of 3 kg and cycle times as low as 0.5 seconds.

The ultra-compact KR 6 SCARA with a 6-kg payload positions at a repeatability of +/- .02 mm. It offers reach/radius options of 500 and 700 mm and a Z-axis stroke of 2 mm. The KR 6 SCARA is strong, fast, highly efficient and delivers maximum efficiency and economy. Both robots were paired with KUKA.VisionTech that provides powerful tools for 2D object recognition, quality control as well as code and optical character recognition.

KUKA’s KR 6 AGILUS with its extreme versatility and agility rounded out the FMCG robotic trio. Adapting to any installation position, the six-axis KR 6 AGILUS is designed for particularly high working speeds, boasts a 10-kg payload and comes in a wide range of variants for challenging applications such as clean rooms and potentially explosive environments.

Working with the three cell-based robots and completing a fully automated end-to-end solution for FMCG-related applications was KUKA’S KMR iiwa that combines the sensitive KUKA LBR iiwa lightweight robot with a mobile, flexible platform. Designed to move omnidirectionally and execute 360-degree rotations, the KMR iiwa is autonomous, reacting immediately if a person or object is in the way, and achieves a positioning accuracy of up to +/- 5 mm. Equipped with a KUKA AIVI control system that uses artificial intelligence to direct automated guided transport vehicles, the KMR iiwa ensures optimum material flow to the production line.