Steam, pressure, time and temperature represent the four parameters of steam sterilization, which is executed within an autoclave (steam) sterilizer to destroy microorganisms to prevent potential disease transmission.

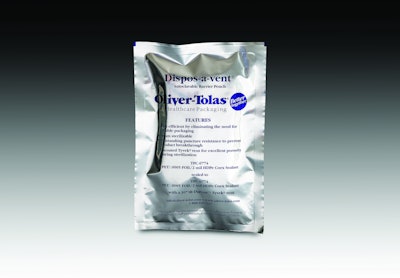

Many medical device manufacturers sterilize in one package and then seal the sterile package in a second barrier pouch to provide moisture protection. But the new Autoclavable Dispos-a-vent® Barrier Pouch from Oliver-Tolas Healthcare Packaging enables sterilizing in one porous package. The pouch withstands the high temperatures of autoclave sterilization, and provides barrier to moisture for devices requiring moisture to remain in the primary package after sterilization and until point of use. The Autoclavable Dispos-a-vent Barrier Pouch is designed with a disposable Tyvek® vent for maximum airflow during autoclavable sterilization.

By eliminating the materials that a second pack would require, the barrier pouch improves efficiencies, reduces costs, and enhances sustainability.

The pouch’s innovation and functionality helped it earn Flexible Packaging Assn. honors with a Gold Achievement Award in Technical Innovation.

Although the package is in use commercially, the Oliver-Tolas customer asked to remain anonymous.

The pouch delivers technical innovation since the porous vent used in the pouch’s design is not blocked by adhesive, which increases the breathability of the package. This characteristic allows for more efficient gas sterilization cycles, increasing throughput and lowering costs.

The pouch employs a high-barrier foil lamination that provides maximum moisture and oxygen barrier properties to extend the shelf life of the device. The puncture-resistant, high-density polyethylene coextruded sealant layer prevents tray edges or sharp ends of medical devices from puncturing the pouch.