He or she has to work closely with many cross-functional groups to ensure key stakeholders have all their requirements taken into account for a package to be successful in the marketplace. The package, and how it is presented in the marketplace, is the first thing end-users will see and interact with to get a lasting impression, whether it is positive or negative. This will provide a good idea of how successful it will be.

One of the first things to take into account is the type of materials to be used for the primary package. The product development group will need to provide the characteristics of the product and desired shelf life. This will dictate the types of material to be used from a barrier and functionality perspective.

Food for thought

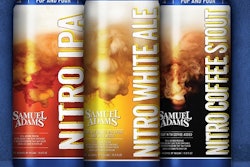

The intended end use needs to be taken into account when designing the appearance of a package—it sounds logical, but often not enough thought is given here. If it is a retail package, graphics will play a big role in how the package is presented to the consumer. If the product is to be marketed only to distributors and foodservice operations, external graphics are less of a concern than other factors, such as cost.

Collaboration with marketing and sales departments is critical to ensure these requirements are defined and considered.

The type of distribution channels to be utilized is another key area to take into account when designing the primary package as well as the secondary and/or tertiary packaging.

The optimal finished product unit configuration is important, and is an area where some critical mistakes can be made if the right questions aren’t asked. For example, to optimize transportation costs, the volume of the finished unit needs to be analyzed to ensure it fits best into the transportation method. Good questions need to be asked about height, weight, and area constraints, which all need to be compared against each other to make sure the transport vehicle is fully utilized. You don’t want to be shipping air.

Also an underconsidered aspect of transport packaging: A package being shipped via railcar will have different requirements than a package shipped via truck. The vibration frequencies experienced vary greatly from roads, rail, or water transport. The mode of transport will affect how much cushioning will need to be considered in the secondary and/or tertiary packaging to avoid damage.

The environment a package is being shipped in is a critical matter. A refrigerated or frozen environment will have different requirements than an environment where ambient temperatures prevail. Condensation/high moisture will directly affect the strength/effectiveness of certain types of materials over time. Other materials may have low or high temperature constraints, which need to be defined up front.

Consult the transportation/distribution group

All this information can be ascertained by consulting with the transportation/distribution group within an organization.

Last, but just as important, the economics of the package need to be evaluated to ensure the package will not make it cost-prohibitive in the marketplace. In many cases, the package costs more than the product. Hence, package cost will have a large effect on the final cost of the product in the marketplace. Direct input from marketing, sales and accounting is vital to this aspect so it can be positioned accordingly.

In many instances, the packaging engineer has to combine all the desired requirements in consultation with the various stakeholders, and discuss options and alternatives, since not all aspects can be delivered in a functional, cost-effective manner. For example, if marketing wants the package to have a certain look or feel, but it will hinder manufacturing and/or increase costs, compromises are needed. The various stakeholders have to come to a consensus, even if it is not the exact solution a given stakeholder would like.

These are just a few aspects to be considered, nor is this meant to be an all-encompassing list. Communication and interpersonal skills also are essential. It is clear that a food packaging engineer has many roles, responsibilities, and interactions with a number of different cross-functional groups in developing a package.