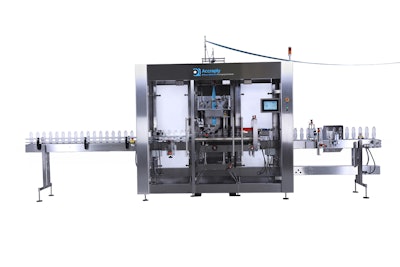

Debuting at PACK EXPO Las Vegas from BW Labeling (formerly Accraply) is the new Graham + Sleevit Shrink Sleeve Model VF650 shrink-sleeve label applicator, which the company says was designed to address their customers’ growing need for labeling solutions that can run sustainable, low-gauge films. The new system also features a small footprint and a new safe-guard system that has been ergonomically designed for ease of use.

Among the materials accommodated by the Model VF60 vertical-feed (VF) applicator are polyvinyl chloride (PVC), rPET (recycled PET), PETG, oriented polystyrene (OPS), and polylactic acid (PLA). The system operates at speeds to 650 products/min and can handle sleeve lengths ranging from 30 to 300 mm in dia and lengths from 28 to 170 mm.

The machine features a state-of-the-art servo film feed that is said to facilitate easy setup and provide accurate sleeve placement, a design philosophy that BW Labeling explains has been used on its full range of full- and part-body sleeve applicators. The company adds that an HMI interface simplifies operation.