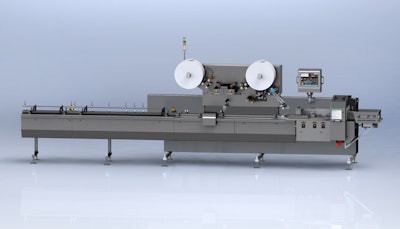

Campbell Wrapper’s new Revolution HS flow wrapper features Allen-Bradley servo drive technology with 5700 Kinetix drives and VPF servo motors, a PanelView Plus 7 1500 touchscreen, an easy-clean sanitary design, and quick changeover, and is capable of running both cold seal and heat seal films at speeds to 1,200 packages/min. The wrapper offers servo-driven film roll spindles, feed rolls, independently driven fin wheel assemblies, and a fin turner and cutting head for accurate cutoff adjustment. According to the company, the wrapper features state-of-the-art film tension control, film splicing with enhanced ergonomics, automatic web tracking, and a sanitary modular design.