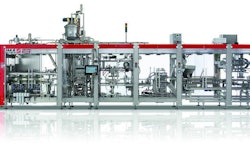

SACMI Packaging & Chocolate exhibited at PACK EXPO Las Vegas its oven-to-case turnkey solution. Featuring product handling and complete packaging for products, the system preserves the integrity and quality of baked products that have surface coatings or ingredients, or those with irregular shapes and edges.

The system consists of a primary work cell equipped with delta robots that groups pieces. Thanks to the SMART PICK gripping system, robots are able to handle single pieces and form individual stacks in one to four pieces per stack before feeding them to the JT Pro Flow wrapper. Upon exiting the flow wrapper, the individual packs are transferred into boxes in the mono-block frame. The secondary packaging cell forms, fills and closes the finished boxes.

To see the SACMI Packaging & Chocolate turnkey solution, visit Booth 7224 in the Upper South Hall.