A factory acceptance test (FAT) is critical for verifying capital equipment operability prior to it leaving a supplier’s factory. Unfortunately, FATs are often overlooked or underdeveloped in the early stages of a project. This often leads to unnecessary costs, delays, and difficulties in later stages.

John Giles, Manager, Operations Engineering Group, Amway, shared a Consumer Packaged Goods company’s perspective on running a successful FAT during a recent PMMI and OpX webinar titled Improving project results using factory acceptance testing (FAT) best practices. Giles is uniquely qualified to address this issue, as his team is responsible for identifying, purchasing, installing, and qualifying process and packaging equipment for Amway North America.

“At Amway we conduct more than 15 FATs each year, and that covers a wide range of equipment—both processing and packaging,” said Giles. “This could be a $50,000 labeler up to a $2 million dollar filling machine.”

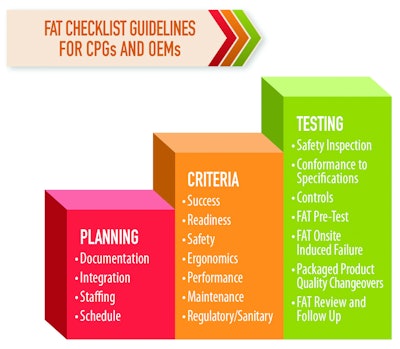

Amway was looking for a standardized approach to FATs across the organization, and the development of an OpX protocol, a work product, and an accompanying checklist called Factory Acceptance Tests: Protocols for Capital Equipment in the CPG Industry, tied in well with Amway’s plans to positively impact equipment start-up.

“We wanted to rapidly accelerate to reach target performance levels,” Giles said. “We want this equipment to go in and run extremely well when it gets integrated into a line, or if it’s a new line, [run well] from an OEE standpoint. We felt that if we could do a better job upfront, we could help with our results with production ramp-up and achieve higher sustainable OEEs sooner in the production environment.”

The FAT work product and checklist from OpX emphasizes that it’s unwise to overlook that upfront portion of the FAT. Planning comes first on the checklist, and within the planning section, staffing is the number one element.

Staffing includes the labor needed to run the equipment during the test, the technical staff required to observe and evaluate, and any others for training purposes. Giles says the complexity of the equipment will dictate who attends.

“In the past, we sent 10 or 15 people. It can become a zoo, and it’s not a good experience. Today, we send our maintenance group, operators, and setup personnel, along with engineering. We love to give these guys initial exposure with the potential for some advanced training, and they can meet up with the OEM personnel. This establishes critical relations that can pay off during equipment start-up,” he said. “From the CPG perspective, you want to make sure that you are going to have the same group of individuals attending the FAT that will be responsible for starting up the equipment when it goes into production.”

From an engineering standpoint, Amway will look at including project engineers, an electrical engineer, and depending on the type of equipment, maybe a process engineer.

The next piece is safety criteria. “Safety is critical, and it’s probably one of those things that was overlooked in the past,” said Giles. “Today we pay a lot more attention to safety, and it’s something you need to discuss before you start executing the FAT.”

Treat the FAT as if it were an operation in your own facility. “Don’t relax your standards and say, ‘we’re just going to run this quick test and then it will be over with,’” Giles warned. A FAT is never successful if an injury occurs, regardless of the equipment performance.

Then comes a FAT pretest. “This is a test we started over five years ago,” said Giles. “It’s really just a two- to five-minute pretest to make sure that everything is working satisfactorily before you start running your 15- to 30-minute (or more) FAT run.”

This test demonstrates that the equipment is ready and will meet the agreed-upon criteria between the OEM and CPG. For a simple piece of machinery, you can run this pretest literally right before you start your FAT. For more complex equipment, two to three weeks is ideal.

“The pretest is a key step to help ensure the equipment is successful and ready to go, before committing the time and money for the teams executing the FAT,” said Giles. “We all have stories where we show up and things aren’t quite what we planned.”

Amway’s pretest team looks at the quality of the product, including dents, scuffs, scratches, jams, etc. But the biggest issue is to make sure the CPG and OEM are in alignment with expectations. “If we spec a machine to run 100 units per minute, is it doing that smoothly? It might be on the edge, but not at 100. That doesn’t build confidence that it will pass a longer test,” said Giles. “Then you have other situations where you are running at the agreed 100 units per minute, but you are stopping every 15 to 30 seconds due to a jam or some other type of fault error. Then you can say, look we need to fix these items before we start the actual FAT.”

Another thing a CPG has to keep in mind during the FAT pretest is to be sure you’re assessing your environment. “You’ve got to keep in mind that this is not your production environment,” Giles said. “Is there enough space? Light? Power? Is it a safe environment?”

The last piece in the OpX protocol is the FAT performance. “The main things you are looking at are your rates, feeds, setup values, throughput, quality, etc.,” Giles said. “There can be some difficulties testing at full speeds depending on what type of equipment you are testing. If you are testing one single piece of equipment, and there’s not a lot of integration around it, you may need to work around being able to do smaller consecutive batch runs versus one continuous run.”

From Amway’s perspective, communication about the FAT performance really starts during the request for proposal (RFP) process. “I can’t emphasize this enough,” Giles said. “You want to be able to say to your team, ‘We talked about this with the OEM, and key individuals here agreed upon these base requirements for the equipment you’re looking to install.’

“I bring up the ‘key individuals’ piece because you might have a case where people are trying to influence or trying to change decisions. You really want to make sure you’ve got the key individuals who are going to make the call on quality requirements, a specific component look, or whatever types of attributes you are trying to impact.”

What if significant changes are required during the project? “You should be discussing those, come to agreement, and document them as the project progresses,” said Giles. “The overall goal is to avoid surprises at the FAT.

“I would recommend CPGs use the OpX protocol and checklists. It’s available to help you standardize FAT executions for your organization and the OEM. The bottom line is the same: Successful FATs lead to better installations, qualifications, and production start-up, which means success for everybody on that project team.”

More FAT resources

Founded by PMMI in 2011, the OpX Leadership Network is a dynamic community of manufacturing, engineering, and operations professionals from more than 250 companies who come together and collaborate on solving common operational problems. OpX develops best practices, work products, and protocols free for industry adoption, including Factory Acceptance Tests: Protocols for Capital Equipment in the CPG Industry. Download the checklist for free at pwgo.to/3821, or visit www.opxLeadershipnetwork.org for the FAT and other work products.

Also, a September 2018 webinar featuring Amway’s John Giles, interviewed above, discussed the value and application of the OpX Leadership Network’s FAT work product through real-world examples. Watch the webinar in its entirety at pwgo.to/3820.