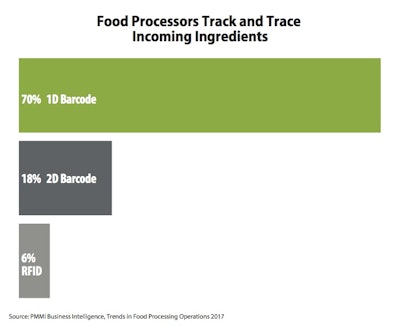

Less than a fifth use 2D barcodes, popular with their peers in pharma for serialization. 2D codes hold more information and food manufacturers are using these codes when they want to include more information (contests, club membership, lifestyle products for branding) to expand consumer engagement.

Even fewer food processors rely on RFID, once thought to be the future of traceability. The six percent who are using RFID for food tracking employ it internally or at the carton level. Some of the responding companies are still testing RFID for traceability.

A director of engineering at a frozen fruit operation said, “We use 1D barcodes and can trace fruit back to the field.”

“…Mostly use 1D barcodes to track large bulk shipments through the transportation chain of custody,” said one engineering manager for a dairy.

All incoming ingredients products are dated with lot codes. In most cases, these are 1D barcodes which are scanned as they enter the plant. This data is linked with internal software intelligence systems and they can then be traced through all phases of processing and packaging.

Source: PMMI Business Intelligence: Trends in Food Processing Operations, 2017.

For more information on pharma track and trace and the use of 2D barcodes download the entire study here.