Some lessons learned the hard way might help someone who has just received the task of automating or tuning a packaging line and hasn’t had that experience yet.

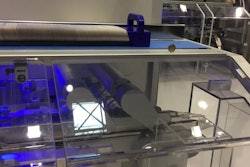

First of all, I would recommend that the automation engineer learn the “personalities” of the machines on the line. Certain machines can cycle quite nicely while other machines can handle speed changes more gracefully than stopping and starting. Some machines like a certain amount of backpressure (containers queued up on an infeed conveyor) in order to improve infeed reliability. There might also be other quirks about any given machine that need to be taken into account when developing the line control logic scheme.

Speed adjustments can have a unique set of challenges to deal with. For example, if glue is being applied to some raw material such as a winder, then how should the glue be managed? It might seem obvious that the glue rate should be simply slowed down in a linear fashion to match the percentage reduction in the speed of the line. Well, I can tell you that what seems obvious isn’t always the case. If the material is paper, that can absorb the glue, and then the glue rate has to actually increase rather than decrease. If the material is something that doesn’t absorb the glue, then I suspect the linear reduction in rate to coincide with the line speed would be a good place to start. If there is some sort of registration marker on the material to facilitate pattern matching on the finished container, and then the line is slowed down, there probably needs to be some adjustment to the timing between when the registration marker is detected and another event such as a cutoff is triggered. In some cases, that timing resolution needs to be more accurate than the timing of a programmable logic controller (PLC) scan can accommodate. In one case, I recall that we had to actually mount the sensor to a mechanism driven by a stepper motor so that we could adjust our timing resolution by simply repositioning the sensor (much like shooting skeet).

Does the packaging line have any sort of accumulation involved in it? There are various forms of accumulation devices from conveyors to vertical accumulators. Speed might or might not be a problem for accumulator management. If you’re counting in and out to manage queue levels in an accumulation conveyor, one question is whether you have enough sensor time for the PLC to catch each container. A high-speed counter might be required to ensure that accurate counts can be maintained. In the case of a vertical accumulator, how much of a gap do you have between containers and what is the reaction time for the vertical accumulator to insert its stop and then elevate a collection of packages?

What about package degradation? How long can you allow the conveyor to run under a stationary batch of containers without damaging the appearance of the package? Is that something that you need to manage? Do you need to synchronize the management of that conveyor with the infeed of the adjacent machine?

There are some filling lines that have multiple stations (coarse, medium, fine) in order to actually get all the material into the container. In powders that are aerated, a vibratory transfer between coarse to medium and then medium to fine allows the material to be settled sufficiently such that the target weight can be obtained within the volume provided by the conveyor. In such an arrangement, I suggest using a one-shot to ensure that a container fill cycle gets started at the proper time so as to ensure a complete filling cycle. If the container isn’t in place at the proper point in the cycle, then you will most likely have a partially filled container and a reject at the check-weigh scale. If you don’t start with a “late” container, then all you have to deal with is an empty container instead of a container partially full of product.

Hopefully some of these hints will prove to be helpful.

Ray Bachelor is chairman of the board at Bachelor Controls Inc., a certified member of the Control System Integrators Association (CSIA). For more information about Bachelor Controls, visit its profile on the Industrial Automation Exchange.