When last Packaging World visited the subject of case-ready meat, Kalsec Inc. was petitioning the U.S. Food and Drug Administration to disallow the use of minute amounts of carbon monoxide in modified atmosphere packaging of case-ready meat. Why? Because, Kalsec claims, it “deceives consumers and creates an unnecessary risk of food poisoning by enabling meat and ground beef to remain fresh-looking beyond the point at which typical color changes would indicate aging or bacterial spoilage.” Kalsec, which makes a line of herbal extracts that can be used instead of CO to maintain meat’s red color, also hired a Washington DC-based public relations firm to, as the American Meat Institute puts it, wage war in the media against the use of CO.

So where does that brouhaha stand now? An article in the December/January issue of Food Safety Magazine, written by Randall Huffman and Janet Riley of the American Meat Institute, sums it up this way: “The FDA is currently reviewing the multiple submissions filed by Kalsec and the responses filed by the makers and users of this technology. As it should, FDA is taking time to ensure that its decision is based upon the available scientific information. If the testimonials from the university experts in support of the technology are any indication of what FDA scientists will find in the literature, the agency will affirm its decisions and reject Kalsec’s petition.”

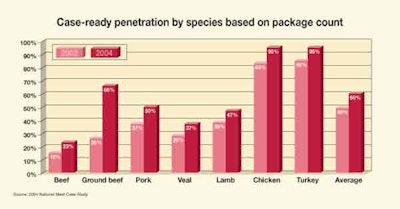

As the CO issue wends its way toward some kind of resolution, case-ready packaging of fresh meat continues to grow (see chart below). Vacuum packaging is part of the mix, though it may never be popular with beef because it deprives beef of oxygen and causes it to turn very dark red, almost purple.

The two packaging formats that are most popular with beef are what might be called MAP Barrier Tray and Backflushed Barrier Masterbag. Both provide a refrigerated shelf life of about 10 days.

In MAP Barrier Tray, a deep drawn barrier tray is backflushed with gases that help prolong shelf life, and the tray is then hermetically sealed with a heat-sealed barrier lidstock. In Backflushed Barrier Masterbag, a large barrier bag contains multiple units of meat in conventional foam trays and clear film overwrap; the masterbag is backflushed and hermetically closed, and once it’s opened, the individual units have a three-day shelf life.

Some retailers like the MAP Barrier Tray approach because they don’t have to worry about the three-day shelf life of the individual packs once the Masterbag is open. Other retailers like the Masterbag approach because some consumers are more accustomed to the more conventional appearance the unit packs have (compare the two in the photos above and left).

The shy and retiring kind

It would be nice to engage meat packers and retailers in a conversation not only about the relative merits of these two distinctly different packaging approaches but about all things case-ready. Unfortunately, most of the key stakeholders in the case-ready arena are reluctant to be interviewed. H.E.B., for example, the highly regarded Texas supermarket chain, is said to have an impressive case-ready meat operation, but the firm declined to be interviewed for this story. Another major player with an impressive case-ready meat display is Target in its SuperTarget stores, where no less than five brands are represented, including Target’s own Sutton & Dodge. But like H.E.B., Target also chose not to be interviewed. The same was true at Wal-Mart, National Beef, and Packerland Packing, part of the Smithfield Beef Group.

It was a slightly different story at Cargill, one of the packers that supplies SuperTarget’s meat cases. Cargill spokesman Mark Klein acknowledges that Cargill offers both the MAP Barrier Tray and the Backflushed Barrier Masterbag approach. But they also vacuum package for some case-ready programs, and in many cases they send retailers sub-primals that aren’t case-ready at all. Klein believes case-ready will continue to expand, but he doesn’t believe it will ever command the 90 or 95% share of market that is seen in the United Kingdom.

“It’s not a question of will the meat case one day carry nothing but case-ready meat,” says Klein. “There will be a mix depending on what customers want. Our goal is to meet customer needs, not commit to one format or another.”

Even as the percentage of meat sold in a case-ready format continues to grow, it’s interesting to note that at least one small regional chain of supermarkets is taking shots at retailers that do carry case-ready meat in the MAP Barrier Tray format. The SuperSaver chain, which has eight stores in Nebraska and is part of Lincoln, NE-based B&R Stores Inc., ran an ad in late March with the headline “Read any good steaks lately?” Showing beef loin strip steak in case-ready packages sold at Hy-Vee, Wal-Mart, and Target, the ad asks consumers to read the labels on these packages, labels that include the Nutrition Facts box. The ad also highlights the presence of such things as beef broth, sodium phosphate, sodium diacete, and potassium lactate in the case-ready meats. SuperSaver beef, on the other hand, is cut and packaged right in the store, says the ad. The parting message: “You won’t see a nutrition label on our beef, because that’s all that’s in there.”

The case-ready king in Mexico

Down Mexico way, at a 200-store chain called Gigante, the folks who head up the case-ready meat program are a little more forthcoming than most of the retailers and meat packers in this country. According to Gigante’s Oscar Guadalupe Gonzales, the firm has been doing case-ready meat for nearly five years now, mostly in beef, pork, and chicken. Only about 5% of it—mostly what Gonzales describes as “value-added” items—is in the MAP Barrier Tray format. About 95% of it is the Backflushed Barrier Masterbag approach.

“The commercial presentation of the foam tray plus overwrap is still the one that focus groups tell us they prefer,” says Gonzales. “They also say they have a problem putting the deeper tray in the freezer.”

Like H.E.B in Texas, Gigante runs its own case-ready meat packaging operations. Its largest one is in Mexico City.

“When we started five years ago there was no IBP or Cargill or Tyson operating case-ready meat plants in Mexico,” says Gonzales. “So we built our own. Recently, a few meat packers in Mexico have established case-ready plants, and we’re beginning to see other retailers offering case-ready meat. But we’ll keep our operation in-house. Gross margins are squeezed if you have an outside packer in the picture. Also, we’re trying to establish standards and to have a consistent look to our meat packages no matter what store they are found in. Running your own centralized operation makes that easier to do.”

In-store butchers have not been eliminated at Gigante, says Gonzales. “But finding and keeping qualified butchers is increasingly difficult,” he adds. “Case-ready means we don’t have to rely as heavily on skilled in-store butchers.”

AEP (www.aepinc.com) provides most of the polyvinyl chloride film overwrap used by Gigante, and they provide the barrier masterbags, too. Machines for evacuating and backflushing the masterbags are from M-tek (www.mtekcorp.com).

Gonzales says about 80% of Gigante’s 200 stores now carry case-ready meats. A plant expansion at the firm’s facility in Monterrey will increase output from that facility.

Across the pond

One case-ready format popular in the UK but almost never seen in the U.S. is a back-flushed deep-drawn aluminum tray with a clear barrier film heat-sealed to the tray’s smooth flange. Convenience-driven, it lets consumers put fresh chicken, beef, pork, or even fish in the oven in a cooking container that can be discarded rather than washed.

Lloyd Maunder LTD. of Devon, England, recently tweaked its use of these aluminum trays by switching to a new lidding material: Baripet FL45 from Amcor Flexibles (www.amcor-flexibles.com). It’s a 12-micron polyester with a four-layer coextrusion coating that includes EVOH for gas barrier and a heat-seal layer that comes in contact with the tray flange.

“This new film has better sealing properties and improved clarity, yet it costs a little less,” says Shaun Richardson at Lloyd Maunder. The aluminum trays, says Richardson, are from Nicholl Food Packaging Ltd. (www.nfpfoil.com).

Considering how much emphasis has been placed lately on sustainable packaging, any new technologies in the case-ready meat arena that can bring about source reduction and better cube efficiencies throughout the supply chain is worth examining. A pack with room for improvement from a sustainable packaging standpoint is the MAP Barrier Tray used for beef. Why is it typically so deep? Partly because if the high-barrier lidstock stays in contact with the beef, the meat will be deprived of oxygen—which has been backflushed into the pack—and will discolor. The use of a deep-drawn tray minimizes the opportunity for the meat to contact the lid.

That’s where a new concept from Sealed Air Cryovac (www.sealedair.com) called Mirabella™ shows some promise. It’s based on a patented combination of a double lidding material and a barrier tray. Oxygen is free to circulate between the lower film and the upper. While the upper film is a barrier material, the lower is permeable, so if it touches the beef there is still ample opportunity for oxygen to reach the meat. Consequently, the tray can be considerably shallower than the MAP Barrier Tray typically seen today.

While the Mirabella concept is said to be in test in France, another trend underway in Europe is specific to Germany. That country has nowhere near the penetration of case-ready meat that England has, but the growth of Aldi and other deep discount chains in Germany has created a demand for case-ready. Industry observers say a rush to meet that demand is now underway in Germany.