Radiator Specialty Co., makers of Gunk, Liquid Wrench, and other well known products aimed at car and consumer

markets, takes an unusually hands-on approach to packaging machinery controls at its Charlotte, NC, headquarters facility. The firm's controls specialists are big believers in industrial PCs.

“I believe an IPC gives me far better control over machine designs,” says electrical technician Shawn Lahart. “IPC manufacturers that specialize in open technologies have the kind of technological focus that aligns best with ours.”

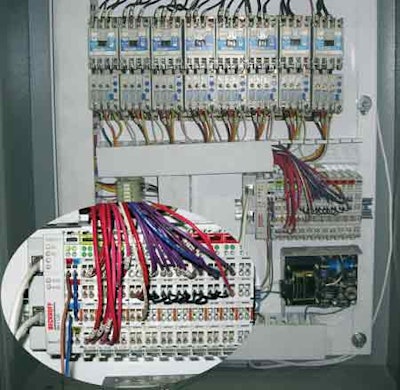

This controls preference runs so deep that on the last two packaging machines the firm purchased, it specified a change from PLC controls architecture to a PC-based design incorporating controls components from Beckhoff Automation (www.beckhoff.com).

“With the PLC approach, we couldn't easily or cost effectively upload and download parameters to the controllers,” says Murray Williamson, engineering manager at Radiator Specialty. “With Beckhoff's TwinCAT software and IPC hardware, the transfer of parameters and settings is a breeze. Most of the functions we use are already included in TwinCAT.”

A critical deciding factor for the Beckhoff approach was the Automation Device Specification (ADS) messaging protocol, which Beckhoff calls the “nerve system.” ADS-enabled devices—that is, any PC running TwinCAT and all Beckhoff BC Bus Controllers—are automatically scanned by TwinCAT System Manager. I/O data is imported via ADS and is mapped to the PC quickly, which greatly reduces programming time.

Four of the plant's filling and packaging lines are controlled by Beckhoff C6320 or C5102 IPCs communicating via BK9000 Ethernet TCP/IP/I-O Bus Couplers. A variety of Beckhoff control panels equipped with touchscreens are used as the HMI. The Beckhoff IPC runs both the machine control and the line's HMI. I/O Bus Couplers are deployed around the lines in a distributed I/O architecture to reduce wiring efforts.

The majority of the firm's networking is now done via Ethernet TCP/IP. Lahart and Williamson determined that industrial Ethernet paired with PC controls was a cost-effective way to network

production machinery and brought great benefits for uniting the manufacturing and corporate networks to access valuable production and recipe data.

“Achieving this any other way is often too expensive,” says Williamson. “In addition, Ethernet is one of the most stable and noise-tolerant methods of machine communication I've worked with.”

The newest packaging machine at the plant, a capper for containers of Gunk products, is the facility's first major EtherCAT implementation.

“One key motivation for using EtherCAT was that we didn't have to use switches—CAT5e cabling goes right to the EtherCAT I/O Bus Couplers,” says Williamson. The changeover to EtherCAT, says Lahart, went quickly. “We just purchased an off-the-shelf, dual Intel Ethernet card for the IPC controller, crimped up another CAT5e patch and went from single-port, real-time ADS to dual-port EtherCAT with redundancy. The complete conversion took about an hour.”

Radiator Specialty has also upgraded its other capper machines to the latest Beckhoff software offering, TwinCAT 2.10, largely due to its comprehensive support of EtherCAT. “TwinCAT also comes in handy when creating our low-cost HMIs,” says Williamson. “We can develop exactly what we want using MS Visual Basic® and everything is tied in securely to our corporate servers without any problems. All our PPCs have at least two Ethernet cards—one connects to the corporate network using regular TCP/IP, the others are dedicated for real-time TwinCAT or EtherCAT.”

“With our upgrades and line integration, we were able to achieve production increases from our machines ranging from 10 to 20 percent,” says Lahart.

—Pat Reynolds