This survey was developed with assistance from Packaging & Technology Integrated Services (PTIS), a consultancy that helps companies better integrate packaging into an overall management strategy. The goal was to assess just how important the packaging function is in product development efforts and to show where packaging as a discipline is today. The survey also suggests where packaging needs to get if it is to have a greater impact on profitable product innovations.

This survey represents perspectives of both large and small companies. Respondents are from companies with more than 2ꯠ employees and from companies with fewer than 100 employees.

Approximately 37% of the respondents were from companies with more than 2ꯠ employees. Another 29% were from organizations with from 500 to 2ꯠ employees. Only 13% were from companies with fewer than 100 employees, while 21% were from companies with 101 to 500 employees.

Packaging World acknowledges the contributions of PTIS principals Michael Richmond and Brian Wagner. Their help in formulating the survey questions and interpreting the results bring added value to the overall effort.

How important a role does packaging play in product development efforts right now? Where and how should fundamental packaging issues fit into product development strategies at Consumer Packaged Goods (CPG) companies?

Those who responded to a targeted survey on packaging and product development say that packaging plays a significant role about one-third of the time. But they say packaging should play a key role about 70% of time, leaving a lot of room for improvement.

Packaging World ran its on-line survey early in 2005, and it got more than 200 responses. Top-line results from the data and the analysis show:

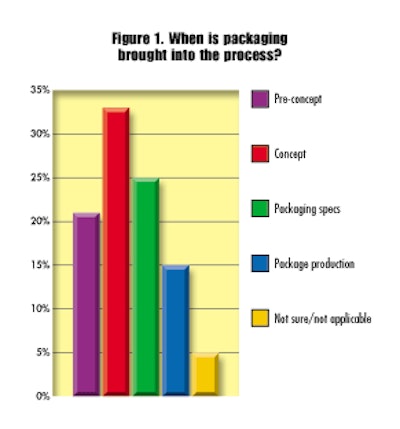

• About 21% of respondents say their company’s packaging department is brought in at the pre-concept stage and 33% say at the concept stage when a new product is being considered (see Fig. 1). They say packaging professionals collaborate closely with marketing as product and package evolve.

• Asked what the ideal collaboration picture should look like, more than two-thirds of respondents say the packaging department should be brought into the product development process early (see Fig. 2).

• Marketing drives the product development process. Marketers are involved in early pre-concept thinking 46% of the time (see Fig. 3). Packaging people get into pre-concept development only 21% of the time.

• Survey respondents see packaging as the most important function in the process, saying that 77% of the time the packaging function is “very important” in product development (see Fig. 4). Purchasing is lower on the product development “totem pole.” Its influence is considered “very important” only 31% of the time.

• In many cases, the concept of integrating all the players—including vendors—into an integrated value chain hasn’t happened yet.

• One of the more significant obstacles to effective product development—the “not invented here” syndrome—is going away, and managers are quicker to embrace ideas from outside sources.

The on-line survey, “Where Packaging Ranks in the Organization,” went to a broad e-mail list of Packaging World subscribers. More than half of those who responded were from CPG companies. The others were suppliers and consultants. The percentages reported in this article represent only responses from CPG companies.

Defining integrated value chain

The survey’s goal was to determine to what degree companies are implementing the Integrated Value Chain Model (IVCM) for managing packaging. That model seeks to involve packaging with all other functions in developing and delivering new products. In simplest terms, it suggests an easy flow of information among these internal functions:

• marketing

• market research/consumer insight

• packaging

• manufacturing

• purchasing/procurement

• supply chain/logistics

The integrated value chain model also calls for external input into the process. Key external insights come from material and machinery suppliers and outside consultants. It would also call for retailer insights, either from retailers themselves or from research on retailers.

To assess where CPG companies are in adopting the IVCM, the survey asked respondents what role packaging plays in the product development process. Fig. 5 summarizes the responses for packaging.

Fig. 2, on the other hand, shows what respondents wish their companies were like when it comes to integrating packaging into the product development process. A whopping 72% said they’d like to see the packaging department more meaningfully engaged.

Mike Richmond, CEO of Packaging & Technology Integrated Solutions (PTIS), believes that the results shown in Fig. 5 represent an overly optimistic view of what’s really out there today.

“When I see 37% of respondents saying their packaging department is actively and appropriately involved in product development, I think some of that is wishful thinking,” Richmond says. “They understand what the goal is, but they overestimate their company’s progress toward that goal. We see the packaging people understanding how the process should work, but we don’t see it actually implemented at that high a rate.

“Very few companies are truly there,” Richmond continues. “One thing lacking is insight into what consumers think about packaging. Companies have to develop a plan and program to fill the gap and better integrate solutions.”

Richmond’s contention that packaging departments today are not being deployed effectively is supported by the survey results shown in Fig. 1. It shows that just 21% of the survey respondents said packaging is brought into the project at the pre-concept stage. Richmond sees this as a mistake.

“That pre-concept stage is a key,” Richmond elaborates. “This is where CPG companies identify consumer needs and dream up the concepts that can satisfy those needs. It is where packaging ideas enter the process.”

Brian Wagner, Richmond’s partner at PTIS, couldn’t agree more. “If packaging professionals wait until the concept stage to get involved, it’s basically too late,” says Wagner. “By the concept stage, the process has passed the point where fresh ideas are being kicked around. When you reach the concept stage, you’re fleshing out ideas, you’re putting words and pictures on a board. If packagers don’t get involved sooner, too often they’re simply told, ‘Use this packaging format. We’ve done that before and it’s worked okay.’ Packaging professionals need to get involved at the pre-concept stage because that’s when it’s still about ideas. By the concept stage, ideation has already given way to implementation.”

Further analysis of the survey results would indicate that the majority of CPG companies continue to look at product development as a linear process. In that scenario, marketing or senior management comes up with the idea in the pre-concept or concept stage and then hands it off to packaging. Packaging, in turn, hands it off to purchasing and operations.

Further down the value chain are external resources. A look at Fig. 4 shows that just 28% of respondents believe converters were “very important” in product development. Raw material suppliers and external resources such as outside consultants fared worse at 23% and 18% respectively.

According to Wagner, CPG companies that fail to involve external resources early in the development process are missing an opportunity to bring innovation into the process. That leads to less than optimal solutions.

“Converters have thousands of ideas on their shelves,” says Wagner. “But nobody knows what all those ideas are, and nobody is bringing them to the table early. Those ideas may be solutions that have worked in the past and have a particular application to a current need. But the ideas remain sequestered in the converter’s institutional memory.”

Opportunity for converters

Richmond says this situation spells opportunity for converters and raw material suppliers. “In a truly integrated value chain model, suppliers, converters, and other external resources would be bringing ideas to CPG companies. If those suppliers get consumer insights, they can use that to gain entrée with CPG companies. If a vendor with an easy-open technology links that to lifestyle research which says the consumers have problems in a particular situation, this technology can address that.”

Wagner provides another perspective, “Consider observational research, looking at how a consumer deals with a packaging issue. If the raw material suppliers and converters are involved along with the GPG company’s marketing and packaging people, they can bring solutions to the table. That is the integrated value chain model in the truest sense, but there’s not much of that being done today. It’s unfortunate, because the benefits to be gained include quicker speed to market, lower cost, and product differentiation.”

Fig. 4 identifies another resource that does not get integrated into the product development process to the extent that it should: the retailer. Only 33% of the survey respondents viewed retailers as “very important” in the product development process. Richmond believes retailers should be brought into the process earlier because they know what sells—multipacks versus single containers, large sizes versus small sizes, and so on. “CPG companies have to understand their distribution channels—retailers such as dollar stores and club stores are different channels. You have to have their input to get efficiencies from the product development process,” Richmond says.

Where to go from here

A small core of CPG companies understand packaging’s key role in product development, and this first-time survey provides a benchmark on the extent of the involvement. “These are companies where the senior management is driving the process from the top down,” Wagner says. “A lot of packaging professionals focus on the technical aspects of their jobs. But to really drive packaging’s role home, they have to sell what packaging can do to their top management. That’s how packaging will achieve its full potential.”

Jim Peters, CPP, is a writer and packaging consultant who helped shape the concept and scope of this study.

See sidebar to this article: Lost opportunities in consumer and market research