Let’s say your company is a contract development and manufacturing organization (CDMO) headquartered in Europe. You might think your firm could take some time to develop its serialization and aggregation efforts, right? Wrong!

For Latina, Italy-based CordenPharma Latina, the company is ahead of the curve when it comes to track and trace, serialization and aggregation as a full-service partner in the contract development and manufacturing of Active Pharmaceutical Ingredients (APIs), drug products and associated packaging services to the global pharmaceutical industry.

Key to the company’s success in addressing serialization and aggregation is its relationship with supplier partner Adept Packaging, a packaging engineering and consulting company (see sidebar below).

CordenPharma Latina’s assertive position is understandable given that it is part of a network of CordenPharma manufacturing facilities across Europe and the U.S. The company is organized under five technology platforms:

• Highly potent and oncology, antibiotics and peptides

• Oligonucleotides

• Lipids and carbohydrates

• Injectables

• Small molecules

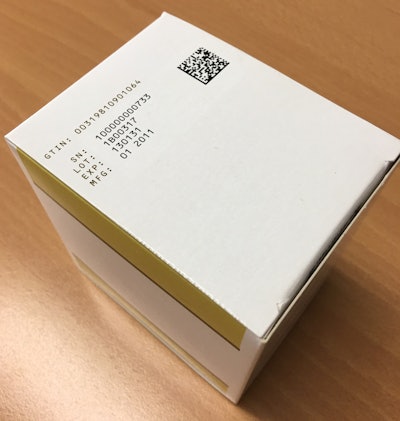

CordenPharma’s three major drug manufacturing departments—oncological, cephalosporin and penicillin—produce tablets and vials packed into primary packaging formats such as blisters, cartons and bottles. All manufacturing and packaging is performed within the CordenPharma Latina facility.

In this question-and-answer session, CordenPharma’s Mario Scigliano, Serialization and Drug Product Maintenance Manager, addresses serialization, DSCSA compliance and related issues.

Healthcare Packaging (HCP): Pharmaceutical manufacturers see serialization compliance involving a considerable investment in capital and time. How does your company justify these investments economically?

Scigliano: As a global company, CordenPharma determined that in order to secure business for its pharmaceutical customers, the drugs produced must comply with multiple market requirements worldwide. Securing the drugs against counterfeiting, diversion and loss by applying serialization as a feature serves two main purposes: compliance and business opportunity. CordenPharma’s management considers ongoing investment into the functionality and technology for serialization as necessary for the pharmaceutical market and important in securing business as a CDMO.

How does your company view serialization and/or aggregation? Do you do both at the same time? Do you have personnel assigned specifically to these tasks?

CordenPharma implemented aggregation as part of its serialization systems right from the beginning. Since it will be part of regulations and client requirements within the next few years anyway, it made no sense to invest twice into infrastructure, software and business process changes. Now, CordenPharma is ready to serve the industry with full compliance.

The aggregation data also enables CordenPharma to improve internal visibility into product movement, inventory, warehouse processes and shipping, which adds to business control improvement. Also, any type of rework, recalls and returns are now handled in a much more controlled environment, since the serialization and aggregation data allows for quicker access and identification of products. The CordenPharma serialization team includes nine experts, all equipped with Adept resources dedicated to all serialization, aggregation and track-and-trace projects within the CordenPharma Latina serialization program.

Describe how you began working with Adept Packaging, and for what specific needs and requirements? Why Adept Packaging as opposed to other vendors? What benefits does Adept Packaging provide your company?

Adept Packaging first started working with CordenPharma as a resource provider more thanthree years ago,to support the development of documentation for serialization validation. Over the years, CordenPharma developed an appreciation for Adept Packaging’s competence in industry compliance, validation execution and implementation of serialization, so the relationship grew into a long-term partnership.

Additional Adept Packaging resources were added and the spectrum of services Adept Packaging provides to CordenPharma widened. Adept Packaging resources helped CordenPharma to shape the program, manage projects, handle vendors, maintain artwork/product changes and gain access to their expertise in serialization, GS1, EPCIS, market regulations and pharma standards.

How many packaging lines do you run? How many of these lines had to be made “serialization-ready”? Please elaborate on what equipment was added, where on the line it was added, and for what purpose?

CordenPharma Latina runs 10 packaging lines. So far, three lines are serialized. We mainly added secondary packaging equipment including a cartoner, bundler and case packer. In addition, semi-automated and manual systems were established, handling the serialization part automatically while the aggregation part is manual. At CordenPharma Latina, cartons are mostly handled as SKUs, which are packed into cases either individually or as bundles.

We selected local machine and serialization vendors, which make access to them more convenient and they access our facility within shorter timeframes. Today we are serialization-ready in two out of three departments, with full serialization expected by 2019.

Did or do these machinery changes have any impact on the packaging components and materials you use? If so, how?

Yes. The new machine and handling systems forced us to streamline our formats and sizes due to machine limitations. We had to review and modify packaging formats for cartons and cases. On the other hand, this “force of change” also improved our variety of materials and stock-keeping, which therefore reduced the cost. We have fewer formats now but can order higher quantities of those formats, which is a business improvement.

SIDEBAR STORY

Adept Packaging Examines Partnering Progress

“Corden leadership’s Emilio Frongia (CEO) and Mario Scigliano (Serialization and Drug Product Maintenance Manager) had the strategic insight to foresee business value in serialization instead of just viewing it as a necessary expense,” says Prateek Lal, CEO & Founder, Adept Packaging.

“We are pleased to see the tremendous progress our teams have made in implementing serialization, including aggregation. This leading position is now fueling top-line growth as a distinctive competitive advantage for Corden. We are appreciative of their partnership and trust in us,” says Lal.

Adept Packaging is a packaging consultancy that provides services and resources for serialization and traceability, packaging development and commercialization, and strategy development. The company serves the life sciences, food and beverage and CPG industries through wholly-owned operations in the U.S. and Europe.