Automation systems that provide lower-cost, compact packaging solutions for smaller-scale and startup companies—and help increase throughput and flexibility—represent a win-win for both packaging machine builders and their end-user customers.

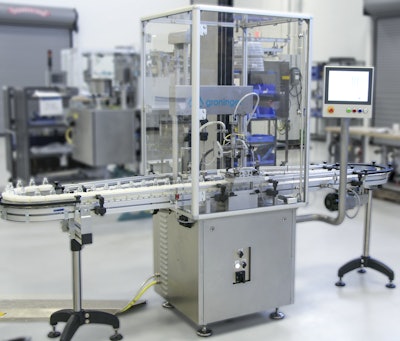

Benefiting from those precise benefits is Groninger, which is based in Germany with operations in North America. Groninger supplies custom filling and packaging machines to the global pharmaceutical and cosmetics industries.

The company provides fully automated high-speed production systems for filling, closing, and handling vials, syringes, and bottles for pharmaceutical and healthcare products, as well as filling, sealing and handling machines for cosmetics such as perfumes, lotions, haircare products, and makeup.

Groninger recently launched the lite-F filling machine, targeting the growing ranks of private-label and startup companies in the cosmetics industry.

A key to the efficiency and flexibility of the lite-F system is its VarioFlow plus conveyor supplied by Bosch Rexroth.

Targets entry-level packagers

Groninger sought to expand its machine portfolio to fill the gap between manual tabletop units and fully automated high-speed production lines.

“We recognized the need for smaller, versatile filling and closing machines to give growing private-label and start-up companies the chance to automate their production with a minimal investment,” says Lothar Burger, Managing Director of Groninger USA.

The first model in the Groninger lite line is the lite-F, a two-headed filling unit that can fill up to 2,700 units/hr and process containers up to 500 mL and/or 16 oz. It processes both glass and plastic containers and works within a compact 460-cm long x 100-cm wide footprint.

It is designed to fill liquids—from water-based products to thicker viscosities such as creams—in a single machine. The machine can replace manual filling systems typically used by smaller private-label companies, enabling them to significantly increase throughput and expand their customer base.

Demo puts VarioFlow plus to work

The lite series represent the first Groninger machines to be designed and manufactured at the company’s Charlotte, NC, headquarters. (The photos for this story are shown at the Charlotte plant.) Groninger’s customers will benefit from the cost-effective systems via increased productivity delivered by using a combination of manual processes and automation.

During the process, workers place empty containers onto one side of a moving conveyor, with containers conveyed to a filling head. The containers are filled one at a time, then indexed by the conveyor to a discharge point.

The continuous, oval-loop conveyor gives plant operators the freedom to decide where to station operators who load the empty bottles and remove the filled bottles for further processing and packaging.

According to Dave Gozlan, Business Development Manager for Groninger USA, at the time that the design for the lite-F was being finalized, senior executives from the company had the opportunity to see a VarioFlow plus demonstration.

“The Groninger and Rexroth technical teams quickly got together to see what we could accomplish,” says Matthias Schiedeck, VarioFlow Sales Manager for Bosch Rexroth. “And with what they were trying to do with the lite-F, we identified specific technical requirements and modifications we would need to do to make the VarioFlow plus work for Groninger.”

Tight turnaround

The latest in the flexible chain conveyor series, VarioFlow plus uses optimized sliding characteristics for the chains and slide rails, fewer joints with low-friction materials, gliding surfaces that do not require machining, and connection technology engineered for easy assembly and modification.

VarioFlow plus is offered in track widths ranging from 65 mm to 320 mm, with in-stock materials including standardized curve sections. In the lite-F, empty containers are indexed into one end of the machine and transported on the conveyor to the filling heads. After filling, they are then transported to a discharge point.

The main challenge the Rexroth team faced was fitting the VarioFlow plus into the existing lite-F design, which was nearly ready for fabricating and was scheduled to debut at a major tradeshow in less than three months’ time. Rexroth had only three weeks to create and ship two custom curves, one with a 7-deg angle and another with a 15-deg angle and modified/customized connection points with longer infeed and discharge sections to fit the conveyor’s closed-loop around the filling station equipment.

The conveyor accommodates the lite-F’s maximum container size—up to 120-mm long x 100-mm wide—as well as transports containers directly on the belt or moving “pucks” that contain multiple containers.

“We knew it was a custom design,” Gozlan says. “But we could see that we could sit down and work with Bosch Rexroth to get a more customized solution, without incurring significant additional costs.

“We’re glad that we found a partner willing to work with us to develop our needs further, which was something Rexroth’s competitors weren’t as willing to do.”

One key tool that aided the team in meeting the tight deadlines was Rexroth’s MTpro software. The Windows-based program for designing and configuring conveyor systems is user-friendly and easy to learn, lets users combine catalog components to form assemblies and systems in a virtual 3D format, with support of a built-in rule engine to ensure the solution will work in the real world.

“We used MTpro to brainstorm with Groninger on how to use VarioFlow plus,” Schiedeck says. “Immediately it helped us determine that an initial component design wouldn’t work, and so with MTpro we were able to quickly work out an alternative set of components to solve the challenge.”

Key benefits

Among the key benefits VarioFlow plus and the lite-F machine offer Groninger are the following:

• Compact size that fits the needs of the machine’s target markets by keeping the overall machine’s footprint down for the smaller private-label manufacturers with limited plant floorspace.

• VarioFlow plus’s easy assembly and interchangeable design features enable manufacturers to modify or expand their footprint in the future. The modular design permits connecting the lite-F to upstream or downstream machines, which helps end users seeking to increase their future automation level.

This will enable the VarioFlow plus to convey filled bottles from the lite-F to a bottle-capping machine that Groninger plans to deploy in the near future.

• Smooth motion. This is important in conveying containers, particularly in filling sequences where there are stop-and-start sequences of motion.

Says Gozlan, “The way the VarioFlow plus works, the connection points are much cleaner and smoother operating than the competition’s, and that gave us confidence that it would deliver the smooth motion we need.”

A new partnership

Both companies are pleased with their partnership’s results. “When you do something custom, as we were doing with the unique angles that we needed with the VarioFlow plus, you expect that cost may be significantly higher,” Gozlan says. “However, what pleased us at Groninger was that, when all was said and done and the components ordered, it still ended up costing less than the competitor’s solution.” Groninger has already ordered a second VarioFlow plus conveyor and plans to consider including it in future machine designs.