Darien, CT-based Zotos International, Inc., a wholly owned subsidiary of Shiseido International Corp., manufactures and markets a full range of hair care and hair coloring products for salons and salon professionals. The company had been using end-load cartoning equipment to package these products. But the equipment was aging and ready to be replaced.

After researching options, Zotos selected a Trayfecta M2 1503 carton former and a Capstone S2 1500 carton closer, both from Delkor Systems Inc.. These forming and closing systems were installed at Zotos at the beginning of 2013 to handle the company’s new three-bottle-per-carton perm kits.

Anthony Perdigao, VP of Operations and Chief Sustainability Officer for Zotos International, notes, “We chose Delkor because it was cost-effective, and Delkor had a good reputation. We selected off-the-shelf equipment that fit our criteria. Customization was not required. Delkor staffers were here during installation, training, and start-up. We were very happy with their services.”

Triple functionality

Delkor’s Trayfecta is so named because it offers “the power of three.” It accommodates three forming options—cartons, cases, and trays—and three container structure options—corrugated, paperboard, and micro flute. In addition, Trayfectas are available in three machine models and sizes to handle servo-driven, mechanical, and retail-ready packaging operations.

Likewise, the Capstone S Closer has the versatility to handle a variety of corrugated or paperboard carton styles, including tri-seal, front flap seal, hood, or hinged, and it features compact, right angle design.

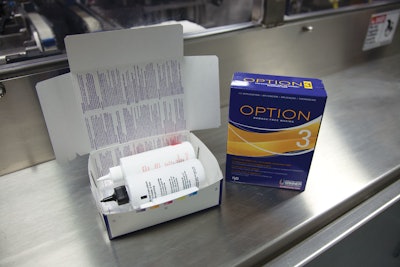

Zotos uses 45⁄16” x 17⁄8” x 55⁄8” cartons for the new perm kit application. The carton flats, constructed from .016 AngelBrite® recycled board from Rock-Tenn, are printed by InnoMark Communications (www.innomark.com). The carton flats are printed in one-color to four-color process, plus metallic ink and aqueous coating. Cartons feature a tamper-evident tear strip and reclosable flap.

The Trayfecta’s ability to form Zotos’ cartons from flat blanks allows Zotos to purchase the cartons at a lower price versus an end-load carton style, Also, the Trayfecta forming approach makes available the largest carton panel to load the various hair perm kit components. The perm kits are composed of three bottles of product—two 4-oz bottles and one 1-oz bottle per kit. Some of the bottles are made of PVC and others are HDPE. Zotos purchases the PVC bottles from Currier Plastics. The HDPE bottles are produced in-house by Zotos in Geneva, NY.

Bottle feeders for Zotos’ operation are made by New England Machinery Inc.. Bottle unscramblers, accumulation tables, conveyors, fillers, cappers, and coders are supplied by Apacks.

The Trayfecta allows Zotos to utilize automatic collation and feeding of the various components that would not be possible with an end-load version of the carton. And the precise positioning and gentle handling afforded by the carton closer maintains the high quality standards of a cosmetic product. The TriSeal carton closing machine features innovative Intelligent Positioning™ technology to consistently align sealing flaps and carton graphics during high-speed operation, resulting in superior packaging quality.

Perdigao notes, “We’re running our new carton forming, loading, and closing systems at about 110 cartons per minute. Our old cartoning equipment was slightly faster, but we get considerably less downtime with the new system. We‘re also encountering significantly less packaging material scrap. And this modern equipment gives us easy access to parts and service.”