Sold at Seattle, WA-based Costco Wholesale Brands’ club stores, the 48-ga polyester pouch is extruded, printed, laminated, engraved (manufacture of the gravure cylinders), and converted by Nordenia USA. DuPont supplies the resin. The package won a Gold award from the Flexible Packaging Assn. for Printing Excellence.

"The original paperboard package not only used too much packaging material, but it didn’t have the graphic presence of the current bag," says Kevin Diegel, associate art director for the Costco Wholesale packaging department. "The Kirkland Signature Ravioli was originally packed in two unprinted pouches that were then packed inside a printed paperboard carton."

A press-to-close zipper allows consumers to reclose the package for multiple uses. The structure also provides good cold temperature strength. Package printing enhances the detail and graphic quality of the entire design, and ensures a quality reproduction on future runs. According to the converter, the printing process also allowed this design to be printed using six colors instead of eight. Nordenia makes the pouches and sends them off to a contract packager for filling.

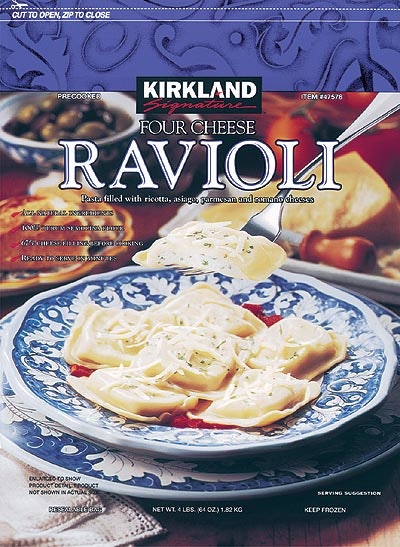

"The colors of the previous paperboard carton were dark and moody, while the new bag is brighter and more sophisticated in its photostyling," Diegel says. "The switch to a life-style photo and the use of blue as opposed to the more traditional red or green gave the Kirkland Signature Ravioli a distinctive presence in the frozen pasta category."