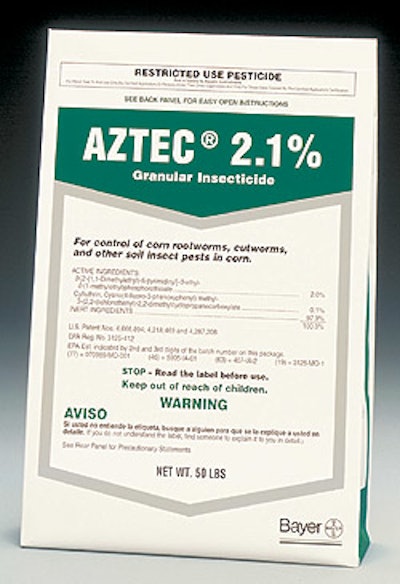

Beginning last fall, Bayer began using a 7.6-mil bag film that provides the strength and moisture barrier necessary for the heavy product, which is sold to corn farmers in the Midwest. “We made a change because we were dissatisfied with previous bag breakage,” notes Susan York, communications manager for insecticides for Bayer, a firm based in Germany with U.S. headquarters in Pittsburgh.

To remedy torn or punctured bags, Bayer turned to its converter American Packaging Corp. (Rochester, NY). APC prints and laminates the structure, then uses bagmaking equipment to produce finished bags that are filled by a contract packager.

At the center of the three-layer lamination is a 3-mil layer of Valéron®, a high-strength, cross-laminated material from Valéron Strength Films (Houston, TX). Valéron is adhesive-laminated to an outer layer of 60-ga biaxially oriented nylon that’s reverse-gravure-printed in three colors and lacquer. The inside layer is a 4-mil peelable coextrusion of linear low-density polyethylene that provides easy opening, according to Doug Mattson, the company’s manager of packaging technology.

“The bags are going through the distribution chain for use with spring planting, so it’s too early to determine how much less breakage we’ll experience with these bags, and how distributors and agricultural growers will react,” says York. “But we anticipate there will be less breakage [with this bag structure], and therefore fewer problems during distribution and for end users of the product.” —JB