As 3Com Corp. prepared late last year to launch Audrey, one of the first so-called Internet appliances, package design was handled, appropriately enough, via the Web. Teaming up with packaging distributor xpedx (www.xpedx.com), Santa Clara, CA-based 3Com took advantage of a Web-based service from application service provider webPKG (www.webpkg.com) that enabled real-time collaboration among all participants in the packaging development process. “I’ve deployed tools in the past that do certain pieces of what webPKG does, but none of them has been as comprehensive,” says Rick Casey, global commodity manager at 3Com and the person responsible for packaging procurement. The key to webPKG is a private Web site set up for a manufacturer’s packaging specifications—in this case, 3Com—that can be accessed by anyone in the world who has an Internet connection and the necessary password. By logging onto this private site, multiple parties can view packaging specifications as they evolve. Iteration is replaced by simultaneity.

No more overnights “In the old days,” says Casey, “as designers came up with something, they’d have a model made of it and overnight it to Chicago, where they’d say ‘yes, it looks good’. Then Chicago would send it to Santa Clara for their comments, and so on. It was a highly iterative process, with only one party viewing something and then passing it along to the next party. With webPKG, it all happens simultaneously among all parties who are involved.” On the Audrey project, that meant fewer prototype shipments via overnight delivery services, reducing delays. They were replaced by much more efficient online proofing of concepts and designs, reports Casey. “Time constraints weren’t such a big issue in this particular case because our group got involved very early on, which meant we had sufficient time to develop a package regardless of which tools we used,” says Casey. “But on plenty of projects we encounter in the future, I could see webPKG as a terrific way to increase speed to market.” Nevertheless, deploying webPKG helped xpedx, which entered the Audrey project in April 2000, to complete its design and sourcing assignments and line up the packaging materials by 3Com’s July deadline.

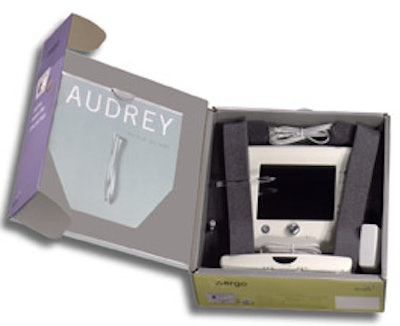

Twelve collaborators Where webPKG really shone in the case of the Audrey package, says Casey, is in the way it allowed no fewer than 12 parties to collaborate as the packaging evolved. They included: • 3Com product marketers in Santa Clara • xpedx in Hayward, CA • a 3Com marketing group in Chicago • an ad agency in San Francisco responsible for graphics • the contract manufacturer in Guadalajara, Mexico, that actually makes Audrey • an xpedex office in Guadalajara • a foam fabricator in Guadalajara • a corrugated converter in Zapopan, Mexico • a litho sheet converter in San Jose, CA • a label supplier in Pleasanton, CA • a plastic handle maker in New York and • a polyethylene foam sheet supplier in Compton, CA. The finished package concocted by these collaborators consists of a 200#-test double-wall corrugated book-style box. Both corrugated media are E-flute, and the outer linerboard is preprinted offset in six colors. The Audrey unit—a $499 computer-like appliance for the home that simplifies access to e-mail and the Web—is cushioned inside the box by two polyurethane side caps.

Distance no object As the above list of suppliers makes clear, not only were there a lot of players involved, but they also were spread out across two countries. But distance is no object to a Web-based concept like webPKG. It’s important to note, however, that not all collaborators have access to all data. “Depending on the password issued to each participant,” says Casey, “we control which elements they have access to. 3Com people, for instance, naturally had full access to certain test results and critical CAD files. But access to such things wasn’t appropriate for certain other participants.” The service is available on a per-user subscription basis plus a standard one-time set-up fee. In this case, the cost of the webPKG service was built into the fee paid by 3Com to distributor xpedx, since xpedx incorporates the webPKG functionality within the xpdex site.

Marrying graphics and structure Joe Farned of xpedx provides an example of how webPKG helped different collaborators marry graphic design with structural design. “As we began to design the Audrey package structure and identify sourcing possibilities, a key collaborator was the design agency responsible for developing the graphics,” says Farned. “Packaging graphics suggest a product’s personality, and that personality had to be expressed not only graphically, but structurally, too, and structure was our responsibility. “So it was important that we be able to work hand in glove with that graphics agency to design a structure consistent with Audrey’s unique personality: friendly, easy to use, engaging. “Through webPKG, when new or revised graphics went up on the Web, we were able to review it together in real time right along with the design agency, 3Com and the other collaborators involved. If discussion or comment was required, it occurred simultaneously, not sequentially, which cut so many steps out of the process.”