The Environmental Protection Agency's new pesticide container standards have packaging implications for a range of marketers of farm, lawn, garden and home herbicides and insecticides, depending on market niche, company size, and current packaging practices.

Perhaps the most notable thing about the final rule is what it doesn't require: that manufacturers of diluted and even many concentrated home and garden products—like those sold at Home Depot, Costco, and Wal-Mart—upgrade their packaging.

The EPA had proposed in 1999 that those products be in plastic and paper packaging that meets the Department of Transportation's Level III packaging standards for hazardous materials. Numerous companies protested that proposal arguing that those products posed little danger to the environment. In the final rule, the EPA backed off.

Rich Martinez, chief environmental officer, Scotts Miracle-Gro Co., says only four SKUs in his company's wide product assortment may be subject to the Level III requirement. The packages for those products will have to be tested, and if found wanting, they will have to be upgraded.

The DOT Level III standards address areas such as compatibility, closures, venting, and filling limits. They also prescribe performance standards and related tests that packaging must meet, including drop, leak-proof ability, hydrostatic pressure, stacking, and vibration tests.

But Martinez notes that labels for all the company's products will have to be changed.

Changes are wide-ranging

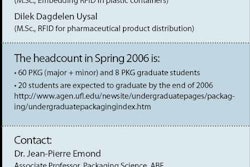

The EPA rule establishes packaging integrity and labeling standards for refillable and non-refillable rigid plastic and steel containers, plastic and paper bags, and aerosol cans. Non-refillable plastic containers in one- and two-gallon sizes—the kind that hold products such as Monsanto's Roundup and Ortho's Weed-B-Gon (pictured)—are heavily used by marketers of lawn and garden, household, and to a lesser extent turf and vegetation control products.

The same kinds of onetime-use plastic containers are also used by non-branded sellers of farm chemicals. Nancy Fitz, the EPA official in charge of the rule-making, says EPA estimates there are

40 million pounds of non-refillable jugs disposed of each year; and they are a chief stimulus behind this final rule, as the agency tries to decrease environmental damage from the land disposal of those plastic containers.

Most large, reputable manufacturers of agricultural chemicals such as Monsanto Co. and Dow use a majority of refillable containers ranging anywhere from 20 to 120 gallons, which have the most utility for farmers and agricultural retailers. They are probably less affected than the “generic” product companies that may have been skimping on packaging.

They are the ones most likely to have to meet the new non-refillable container standards. There, products in what are called EPA toxicity categories I and II, plus restricted use pesticides—these are the most toxic products—must comply with DOT Packaging Category III standards, which specify a range of standards for drop, leak testing, stacking, and other tests a package must meet, within three years. All refillable packages, even those containing less toxic products, will have to meet DOT III standards in five years.

Container size an issue

Tom Hoogheem, stewardship lead, chemical products, Monsanto Co., says a majority of his company's agricultural products are in refillable containers, and already meet DOT level III packaging standards. Ditto for Monsanto's non-refillable farm products. That is not true, however, for many “generic” marketers of farm chemicals rated Toxicity level 1 or 2; many of them are using smaller non-refillable containers that are not DOT Level III compliant.

As opposed to its ag chemicals, Monsanto's lawn and garden products are mostly in non-refillable containers; but they are EPA toxicity level 3 or 4, so they will not have to transition to DOT level III packaging. One of the very big concerns of companies using one-gallon-size plastic containers for home and garden chemicals was that the EPA would also require products beyond Toxicity level 1 and 2 to move to DOT Level III packaging.

This was a real concern for companies such as Monsanto, Bayer, BASF, and others, based on a proposal the EPA made in 1999, which would have required DOT III packaging for lawn, garden, and household pesticides in Toxicity 1 and 2 categories, plus additional products based on their container size and whether they had environmental warning statements on their labels.

In the final rule, the EPA canned the environmental-warning statement and container-size criteria for DOT level III packaging, and instead added a requirement that “restricted use” products—those deemed so toxic they can only be used in restricted circumstances—in non-refillable containers meet DOT III standards. Nancy Fitz of the EPA says no lawn and

garden or household pesticides are in the restricted-use category.

Antimicrobial products

The EPA final rule also affects some antimicrobial products, typically sanitizers and cleaning products used in institutional and commercial settings.

There are four criteria that can exempt antimicrobials; if a product meets all four, it is exempt. If it meets three, it must comply. Generally speaking, according to Fitz, a significant percentage of antimicrobial products will be exempt. For example, household bleach, which contains sodium hypochlorite in relatively low concentrations, will be exempt. Bleach used in swimming pools and spas will be covered.

Household products such as Lysol and others like it will be exempt. So will institutional and industrial sanitizers, for example. The antimicrobials most likely to be covered are ones considered a hazardous waste under RCRA, the solid waste disposal law.

Regardless of whether a covered product is an antimicrobial or a farm, lawn, or home chemical, if it is sold in a non-refillable container it will have to meet other standards beyond container integrity.

For example, the EPA set a rinsing cleanliness standard for non-refillable containers at 99.99% clean. That is referred to as the “four nines” standard. The EPA had earlier proposed a “six nines” standard. In stepping back to a four nines standard, the EPA said about 60% of small, plastic containers are already cleaned to six-nines, and most state recycling programs reject relatively few containers. Thus, a four-nines standard would be sufficient to insure greater recycling. “Therefore, fewer container design changes, re-formulations, and modification or waiver requests will be needed,” the agency said.

The final rule also contains new labeling requirements, which go into effect in three years. Hoogheem of Monsanto calls these “pretty straightforward.” Not surprisingly, given the EPA's objective of encouraging recycling, the biggest labeling changes apply to non-refillable containers. For example, a company has to place the triple rinse instructions on all labels.