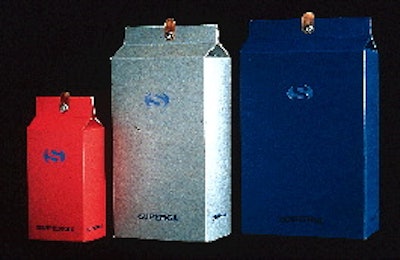

Superga of Turin, Italy, has every reason to fiercely embrace tradition. After all, the manufacturer of rubber-soled sport and casual shoes began as a supplier of rubber tires to Fiat. And those were bicycle tires before Fiat began to build automobiles. This year, the company introduced a broader line of shoes packaged in an innovative new one-piece vertical box. The patented box design and closure is the product of industrial designer and architect Daniel Weil, a partner in an international design consultancy, Pentagram (New York, NY). He credits what he calls "visionary management" at Superga for introducing the new package. It is cost-efficient, durable, collapsible, stackable and it can be reused in the home or recycled, Weil says. It's not only a design change, it's also more protective than the conventional two-piece shoe box. Superga's previous packages were the conventional paperboard boxes that were decorated with three- or four-color printing. "Historically, the old shoe box was made with a good grade of material, and it was frequently reused," Weil says. "But, over time, cheaper materials were used and the strength of the box suffered." Still, Superga's objective was new packaging that would distinguish its brand as the company sought to extend its products from natural rubber-soled athletic shoes into casual, leisure shoes. The new design is also used for Wellington rubber-soled boots. "No packaging system should be accepted as a given," Weil says. "The designer's job is to look for a new perspective, to question pack-aging processes that may have been unchanged for generations, to revisit solutions with a fresh eye and from a contemporary cultural angle. This is the recipe for creating packaging as a 'dynamic expression of the brand.'" This package is based on the geometry of a milk or juice carton, and employs the snap opening device common to doctors' medical bags. The new package is fabricated from wet-strength paperboard, the same material that is used for multipacks for beer. It's supplied by Rexam Foil & Paper U.K. (Middlesex, England). It's very durable, Weil says, and it accepts the design colors well. Rexam converts the board into the package, adds the unusual clasp at the top and ships the cartons flat to Superga for manual loading. Eventually, a pressure-sensitive label is placed on one of the gable sides that displays the bar code, style, size and other necessary information (the photo shown was taken before the labels were completed).