The product was designed to address the requirements of the European Medical Device Regulations (MDR) going into effect in May of 2021 that the integrity of a package is “clearly evident to the final user.”

Additionally, ISO 11607-1 further clarifies that the inspection takes place immediately prior to aseptic presentation. This presents a challenge for uncoated (or coated) Tyvek sealed to PET/PE of Ny/PE which shows minimal contrast at the seal, making it difficult to identify anything but gross seal defects.

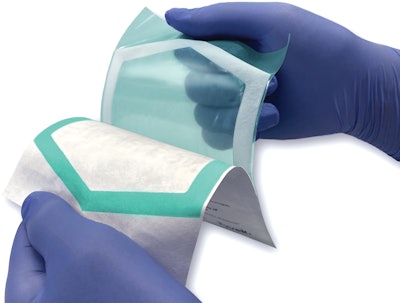

Chameleon “allows the user to readily evaluate the quality of a seal when used with uncoated Tyvek. Prior to opening, the seal shows as a darker color when viewed through the film side. Once the package has been peeled open, a vivid colored seal indicator presents on the Tyvek with a contrasting white seal indicator on the film,” says the company.

Designed specifically to work with uncoated Tyvek pouches, Chameleon consists of an oriented nylon film co-extrusion coated with PAXXUS’ moisture resistant Green Chameleon™ peelable sealant. The cohesive peel allows for a consistent, smooth, fiber-free peel thanks to its unique modified-polyethylene sealant technology.

The bright color of the seal allows the end user to identify any seal defects quickly—which appear in white or a lighter color—even in fast-paced, dimly lit healthcare environments. The seal color can be customized to user branding or for different product sizes or formats.

Beyond the point-of-use evaluation, the system provides the manufacturer an obvious visual distinction between sealed and unsealed areas when visually inspected through the film side in a quick, non-destructive manner.

In terms of sustainability, the uncoated Tyvek (spun-bonded HDPE) can be mechanically recycled in the HDPE stream. Additionally, because the system achieves performance without heat-seal coating the Tyvek, the Tyvek side of the pouch uses 15 to 20% less material than coated options and requires one less manufacturing step.

In what the company calls the “next generation of cohesive peel technology,” seal strength is consistent over a large operating window and the system’s price generally aligns with traditional polyester/poly pouches. The technology has been adapted from its Allegro®T proven film technologies, so support data is available.

The technology is designed to be adaptable to varying thicknesses—the entry product was 76 μm / 0.0030 in. and featured Tyvek 1073B.