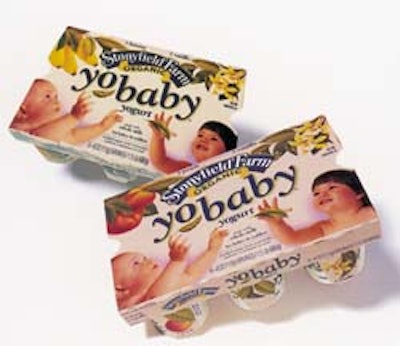

“More than 200-percent above our initial projections,” reports Mary Jo Viederman, director of “Cow-munications” for the Londonderry, NH, yogurt maker.Viederman credits much of yo baby’s early success to the “soft, creamy packaging graphics,” developed with Sterling Group (New York, NY), an international brand consultancy.

Packaging includes an 18-pt SBS outer wrap that incorporates 35% post-consumer material. Offset-printed in five colors, the wrap contains six 4-oz injection-molded polypropylene cups. A 2-mil polyester/polyethylene lidding film is heat-sealed to the cups. Material suppliers and specs are virtually identical to the company’s Planet Protectors™ yogurt multipacks for kids (see Packaging World, Oct. ’99, p. 88 or packworld.com/go/planet). Both multipacks are filled on the same packaging line as well.

“That really helps in our plant,” says Viederman. “We bought the cup mold, and we figured that to amortize that cost, we needed to make 50 million cups. With the addition of yo baby, we’re now close to 30 million. Originally, we estimated a three-year payback on the molds, but now it’s looking more like we’ll achieve that in two years.”

Two flavors of yo baby sell nationwide in natural food stores and supermarkets for $2.99 to $3.19 per pack. “We wanted a really beautiful package for this product introduction, and we have it,” says Viederman.