Ampac FlexiblesFlexible Packaging Association

Companies in this article

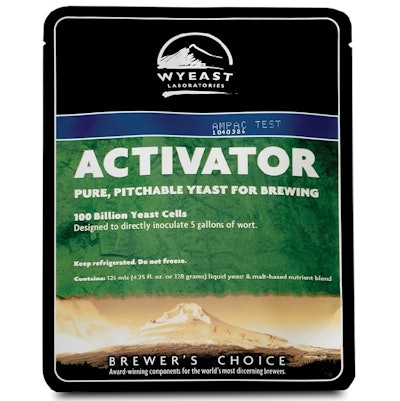

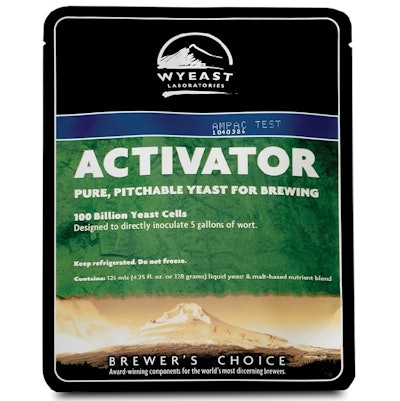

Retorted pouch-within-a-pouch from Wyeast Labs protects sensitive yeast products to gain two golds and highest achievement honors in FPA's annual awards recognizing the best in flexible packaging.