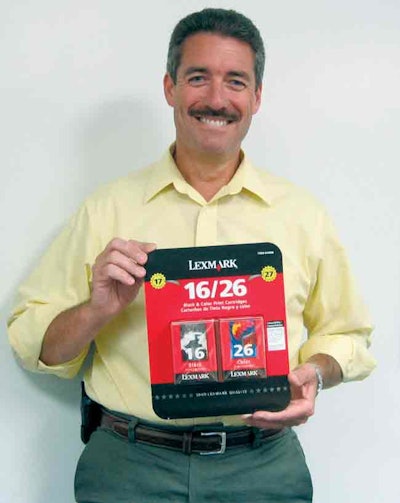

If you were to put a face to the packaging at Costco, it may be that of Scott Carnie, the general manager of Costco Wholesale's East Coast packaging operations in Monroe, NJ.

Thanks in part to his efforts, the company's club store packaging is less brown box and more a spectrum of colorful formats. A key color in Costco's packaging palette is green, as in environmentally friendly.

Some of the most innovatively packaged products appearing in the chain's 488 club stores worldwide are produced by Costco itself. This in-house packaging operation is the principal business of Costco Wholesale's East Coast packaging.

Carnie is the first to point out that the company's in-house efforts, done ostensibly as a contract packaging operation where Costco basically sells to itself, is only a tiny fraction of its overall volumes. Still, that tip of the iceberg makes up in innovation what it may lack in relative volume. However, at the Costco club store level, these volumes would make many a packager envious.

In September, Costco introduced a new five-product line of Lexmark print cartridges in a new kind of packaging. The carded blister-pack addresses issues of theft and is kinder to the environment, Costco says. The packaging is Natralock™ material from MeadWestvaco (www.meadwestvaco.com).

Sustainability with protection

“I knew we had a sustainable option that would reduce the amount of plastics we use and offer the security we need at the necessary cost point,” says Carnie.

It also meets the club store chains' other packaging mandates.

“It's about creating the right package to protect high-value items from shrinkage, but still making the products accessible to consumers,” says Carnie. Natralock's tear-resistant and theft-deterrent properties allow Costco to achieve both goals, he adds.

Natralock's flat surface can be readily opened with a scissors, unlike traditional clamshell packaging with its welded ridges.

According to MeadWestvaco, the card stock portion is 18-pt Coated Natural Kraft® (CNK®) run through a patented extrusion-coating process that applies a heat-seal material, as well as sandwiches the board around a polyester film that provides tear-resisting theft deterrence.

The clear plastic thermoform Costco uses is molded of RPET, not the amorphous PET (APET) as has been generally reported elsewhere.

Costco thermoforms the recycled PET using tooling it made and heat seals the products in the folded paperboard card at this and its West Coast packaging facility in National City, CA.

It's exemplary of materials that are available if you know where to look.

You can eat the package

You may be surprised at what's available—Carnie's idea of that may be more liberal than most. For example, during Packaging World's visit, he pointed to prototype trays from Biosphere (www.biospherecorp.com) that really push the envelop on sustainability. They were part of an informal tabletop display in his office of packaging for projects at various stages.

“The trays are eco-friendly and are backyard compostable,” says Carnie. “And not only could you eat from the packaging, you could eat the packaging.”

Biosphere packaging is made from common, inexpensive, yearly renewable organic resources, primarily starches and a small amount of grass fibers.

According to the company Web site, “Biosphere PPM (Primary Packaging Materials) biodegrade in less than 60 days. Advanced aerospace engineering utilized in the manufacture of PPM products reduces raw material waste and minimizes electrical usage. PPM packaging products are fully microwavable, ovenable and harmless if eaten. The only waste of the manufacturing process is steam.”

Carnie also appreciates that there is no trim waste during the forming process.

There's more packaging in the Costco pipeline, a fact that is the rule rather than the exception.

By the time this article appears, Costco will have debuted an interesting take on Microsoft Xbox 360 packaging. It's a large package that has appeared at Sam's (see Xbox plays to the environment at Sam's Club, published April 2006), but adapted with a unique new design (see picture) to meet Costco's needs.

The packaging comprises two thermoforms that contain the game system and components. The UV-sealed thermoforms are wrapped within an outer frame of corrugated supplied by Interstate Container (www.interstatecontainer.com). The corrugated frame is itself held together by polypropylene strapping. Costco Wholesale operations manager Mark Willis says this provides closure for the corrugated and adds another security measure for the product.

Even if the package is tipped over, Carnie maintains it will be damaged only a negligible amount if at all. The molded plastic contours feature all rounded corners, with no sharp edges more susceptible to cracking if dropped.

Eco-minded multitasking

In another project, Carnie is working with a major consumer packaged goods company that recently unveiled a very striking paper-and-thermoform packaging. Even while that packaging is still “fresh,” Costco is proposing the company move it into an all-paperboard structure. Carnie says the vendor itself saw the format only as restrictive “food packaging” rather than the more universal “product packaging” that he saw. Carnie says the all-paperboard structure is more environmentally friendly and simpler. It is strongly being considered by the CPG company as a candidate to contain a common consumable found in many households, he says.

This is an example where Carnie is somehow able to connect the dots where others may not see a pattern.

To help carry out his vision, Carnie relies on a small, skilled staff of tool-makers. That group originated several years back when Carnie found the turnaround time for tooling unacceptable. Now they have the staff and three CNC machines to produce custom tooling such as molds for Costco's on-site thermoformers. What once took weeks can now be done in hours.

Costco estimates that about 85% of its tooling has been made inside the plant.

Carnie believes that a large part of his staff's effectiveness is because the group “doesn't know that they can't make something, so they have the mindset that they can.”

Carnie has set up Costco's operations so that they can switch out materials to a new one in a hurry. This permits them to adhere to a continuous improvement process for packaging development.

An advantage Carnie has is using a slate that, if not blank, is aimed at using the best available materials for the right reasons.

“We can use anything that works within our parameters,” says Carnie. Besides eco-friendly, those guidelines include packaging that's attractive, efficiently machinable, and provides protection.

Whatever the future holds for Carnie and Costco packaging, it will likely be done in a much larger facility. He anticipates Costco to double the size of this facility from just over 100,000 sq' to near 250,000 sq'.

What is for sure is that packaging conceived by Carnie and crafted by Costco is an unfolding story that will be worth watching in the months ahead (for more on Carnie, see First Person p.25).

Costco earlier this year launched its own Kirkland Signature™ by Borghese private label line of cosmetics (see Costco's packaging makeover revealed, published June 2006)