“We love the product, but your package stinks!” That’s a summary of the reaction that Foss Manufacturing received when it introduced the Fosshield™ Anti-microbial Cleaning Wipe at the 2001 Houseware’s Show in Chicago in January. But it didn’t dampen Foss’s enthusiasm, nor was it unexpected.

That’s because the Hampton, NH-based company was showing off its product in what can generously be called “prototype” packaging. In fact, the company didn’t even decide to show off the product until last October! So it had only a few weeks to develop a package for the show.

“We were sitting around the research and development table trying to decide whether or not to make this product,” recalls Joe Valentino, director of retail marketing and sales for the fabric manufacturer. “So we developed the product and put together some mock packaging materials and had it in a booth at the show in three months.”

Later, after the show response proved encouraging, Foss got serious about production packaging. Working with Industrial Packaging Supply (Worcester, MA), a local packaging distributor that now performs the packaging functions for Foss, the company selected a special header bag that’s printed and converted in Germany. It’s called the tag bag™ and it’s supplied by Fusion Concepts, Inc./Pfankuch (Essex, MA). The company is well known in New England for its equipment for handling and wrapping paper products.

The bag material is made from approximately 1.7-mil cast polypropylene. At the top of the premade bag is the sealed header section that contains a reinforcing strip of 5.5-mil oriented PP. This strip is sealed inside a header section that is later die-cut for pegboard display. The “tag” section is what gives the bag its name, said Edward Marsh, president of Pfankuch in the United States.

Foss is a weaver and maker of fabrics for a wide variety of markets. However, even its products sold at retail require only rudimentary packaging, if any at all. So the Fosshield Cleaning Wipe was new territory for Valentino and his marketing group (see sidebar for product details).

Why this package?

“With this product, we knew it was going up against the majors like Procter & Gamble and other established brands,” Valentino explains. “We knew we couldn’t invest a lot of money into upfront advertising, and we knew the brand name would be new to consumers. Plus, we knew we had a very short time to educate the consumer about the product on the shelf in the store. And with a product like this, that’s crucial.

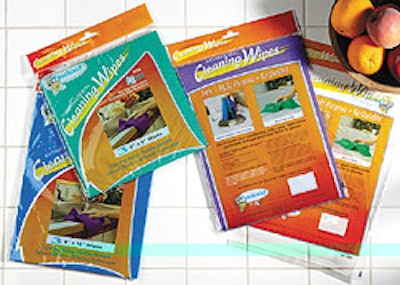

“So we needed something eye-catching, a better package than anything the major brands offered. That’s why we ended up with such a bright colorful pack for a product that is, let’s face it, rather mundane.” Foss worked with marketing consultant Fleishman-Hillard (Boston, MA) for help on graphics.

When it contacted Industrial Packaging Supply, Foss had one other problem: Its initial order volumes would be puny, not large enough to interest many converters in the United States, especially with seven-color graphics.

The bags are printed in seven colors by flexo, including a silver ink that makes the connection to the anti-microbial agent that’s used in the product. The graphics include several process-printed photos, showing how the product can be used.

“We knew that Pfankuch was one of a few companies willing to entertain orders of modest volume, so this worked well with the Foss project,” said Tom Carroll of Industrial Packaging Supply. After the show, Foss and its new partners worked to finalize the package and its graphics. Pfankuch suggested the cast PP material, Marsh says, because its Munich, Germany, plant produces the PP almost in-line with printing, making it easier to deal with small volumes and a short lead time. Plus, he said, the cast material offers strong seals.

“We had to ‘massage’ the timetable a bit to make sure we could get the bags produced and to have enough time to package them.” Carroll says that IPS currently loads the premade bags by hand, then seals the bags on one of several impulse sealers.

Process flexo print

Foss recognized the importance of grabbing the consumers’ attention in the store aisle. “We knew this would be an impulse purchase,” Foss’s Valentino says. “Someone walking through a supermarket or mass merchandiser won’t be looking for this product. Frankly, here in the United States, we don’t use many reusable wipes, even though they’re common in Europe and Asia. So [changing] this attitude is a challenge we need to take on.”

The graphics opportunity is what drew Foss toward the tag bag. It’s an expensive package, Valentino admits, especially compared to a simple film pouch produced on an overwrapper for what he says is about a nickel each. That’s what Foss used to show the product at the January show. “By the time IPS loads these bags, we’ve probably spent 40 cents on the pack, in part because it’s produced and printed in Germany and we have it loaded at a contract packager,” Valentino reveals.

The company did evaluate pouches, shrink wrap, hard blister packs, and virtually every packaging option that would make sense for a $4 retail item. “We’re convinced that we picked the best package for what we needed,” stressed Valentino. He points out that because Foss makes fabrics, the company belongs to a color association and worked hard on both the product and package colors.

Size resistance

Although Valentino reports that retailers say they love the colors and package graphics, Foss has run into some resistance. The basic package holds three 9”x12” wipes, and some retailers have objected to giving it that much space. To counter, Foss now offers a 9x9” product version.

“Everyone’s an expert in marketing,” pointed out Valentino. “We have 700 employees, so we have an in-house focus group of 700. We distributed the product throughout the organization, even going to Australia, Europe, and South America. We asked about colors, sizes and how many they’d likely buy at a time. The nine-by-twelve three-pack was the consensus choice.”

And based on its experience, Pfankuch also fabricated some reclosable bags “on spec” to Foss. This is a bag that looks the same as the original 9”x12” package, but the bottom front panel is a bit longer, explains Marsh of Pfankuch. “We’ve found that once consumers have an opportunity for a reclosable package, they love them. And that’s what’s happened with the Fosshield package.”

As Marsh explains, the company applies a pressure-sensitive tape strip with a release web on it to the longer front panel. In packaging, the worker simply removes the release carrier and folds the front panel around to the back to close it. The adhesive allows opening and reclosing the package several times.

The product is now under evaluation by many retailers across the country. Foss is also working to develop the commercial market for restaurants and hotels.

See sidebar to this article: What makes Fosshield special?