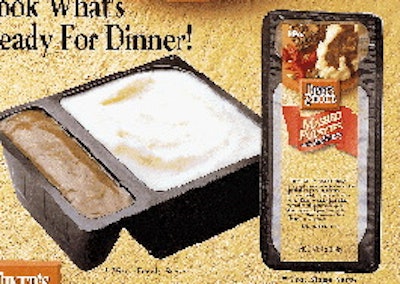

The century's coming to an end (either this year or next) and it's been some time since we've seen a viable new packaging material. Everything that is packaged is still packaged in only six materials: wood, paper, glass, steel, plastic and aluminum. But, what we've lacked recently in pure new material invention, we've more than made up for in material synergies. And those continuing synergies will demand a new generation of packaging professionals, "Renaissance" men and women whose packaging expertise will be matched by their knowledge of product chemistry and engineering in the new century. When it comes to new commercial packaging materials, plastics is the youngest, dating back to about the first third of the 20th century. And plastics developers still occasionally spawn a new polysyllabic polymer for packaging. Polyethylene naphthalate (PEN) had a run of packaging expectancy earlier this decade. Aliphatic polyketones were considered briefly for the production of food cans. Some will argue that the metallocene polyolefins are a new material class, but we haven't heard anyone say they are not plastics. When the 21st century dawns (technically, of course, this will be January 1, 2001), technology synergies, rather than the emergence of a new class of materials (with the possible exception of the commercial scaling up of biological feedstocks), will drive most packaging innovation. The 1990s have witnessed the emergence of a new generation of packaging materials, one I will call the "synergistic generation." The materials in this generation are not new in and of themselves. Rather, they are combinations of materials that work far differently than their individual components. Like a tapestry composed of different-colored threads, synergistic containers will evolve beyond the point where a single material can easily identify them. They will mix the properties, appearances and processability of different materials with inventive outcomes that no single-material package can match. We already have some examples of such synergies. Take glass. Pre-synergistic glass containers went from the lehr to the packer, to the wholesaler/retailer, to the customer/consumer, to the dump or recycling stream as flint, amber, green or cobalt blue ware. Glass bottles had narrow necks sloping gradually to cylindrical bodies. Body walls, inset slightly to keep paper labels from scuffing, mostly were parallel. Neck finishes varied to accommodate lug or threaded closures, crowns or corks. All were cylindrical. Glass containers expected to make more than one trip between the packer and the customer generally were heavier than those making the trip just once. Synergistic glass containers have angstrom-thin coatings to promote lubricity and resist scratching. Closures, once merely leak and spill preventers and product resealers, will take an active role in extending product quality with liners that maintain the precise atmosphere desired within the containers. And labels, once exclusively paper and ink product identifiers, will increasingly cling to glass containers in a host of guises. Appearances will vary from the invisible to the three-dimensional, and in shapes and sizes that range from spots no bigger than the corks they cover to full-body shrink sleeves that sheathe the bottles and evoke a wide range of looks from mystical to metallic. In its "synergistic age," glass will continue to draw from the strengths of all other packaging materials to enhance its appeal as the ultimate product showcasing and barrier material. In this synergistic container era, it's not just materials that are being blended for desired effects. Conventional can-making systems are models of efficiency. But mostly what they produce are boring cylinders with flat tops and bases. Few packagers--and even fewer can-makers to date--have successfully broken the can's cylindrical shape paradigm. One noticeable exception is the series of shaped cans introduced into select venues for short periods of time by Heineken International Beheer BV (Amsterdam, the Netherlands). The cans are a testament to the synergies of container manufacturing technologies. Crown Cork & Seal Co., Inc. (Philadelphia, PA), drew upon the skills of plastic bottle blow-molder Sidel Group (Le Havre, France) to blow mold cans resembling pilsner glasses, mini-kegs, cans entwined with the lyrics to a soccer song and cans caked with mounds of ice. The Crown/Sidel manufacturing synergies add intriguing new depth and definition to the term "blow-molding." Far more common are the packaging synergies being derived from closer development and operational cooperation between product technologists and packaging "technologists." Successful packaging outcomes of such collaborations include aseptic processing and PET barrier bottle packaging of Heinz ketchup. More recent examples include the product and packaging recipes being fine-tuned by Michael Foods, Minneapolis, MN, for its Diner's Choice refrigerated mashed potato and gravies (photo, p. 87). Similarly, the quest by Redi Foods, Burley, ID, for longer-than-21-day shelf life for its pressure-cooked, vacuum-chilled vats of russet potatoes marketed in microwaveable PET trays (see p. 2). Because paper is the least capable packaging material, it is the most synergistic in its approach to the market. Consequently, it is the most widely used of the packaging materials. Unsupported, it generally plays a secondary role as label substrate or cushioning medium. It's still the best printing surface and a malleable material that can be reinforced with metal foils, plastic films and coatings, even glass (in its silica oxide form) and cut, scored, folded, embossed, crumpled and otherwise formed into a wide range of three-dimensional packaging forms. Driven so often by marketing management with little tolerance for state-of-the-art product/packaging production capabilities, successful packaging professionals in this "synergistic era" will need to match their knowledge with: the expertise of a product development scientist, the insight of a customer market analyst and the economic acumen of a cost accountant...all this while working on your Y2K contingency plans!