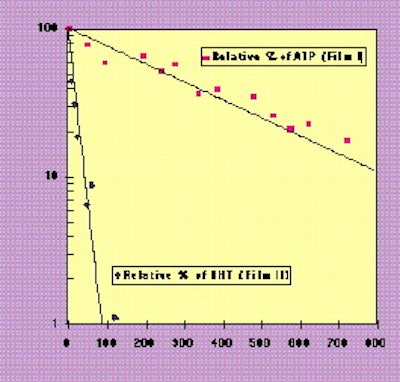

Vitamin E can be a viable alternative to butylated hydroxytoluene (BHT) as an additive in flexible packaging materials to extend shelf life, concludes a recent study conducted by Michigan State University. Ju-Fen Lin, a recent MSU graduate, performed research to compare the antioxidant properties of vitamin E to the properties of BHT in a multilayer laminate structure. The research served as her master's program thesis. The study emanated from the interest of both the food and the plastics industry to find a substitute for BHT as an antioxidant in food packaging. Antioxidants extend product shelf life by inhibiting oxidation of fat in dry food products such as snacks, crackers and cereals. Plus, by adding antioxidants like BHT to the packaging film, food processors don't have to add a preservative directly to the product. This creates a shorter ingredient listing, always a plus with consumers. Antioxidants also confer benefits to film manufacturers and blow molders. The additives help prevent packaging material degradation, improve heat resistance, and control color change during film extrusion or blow molding. For all of these reasons, resin companies have offered materials incorporating antioxidants into polyolefins for years. However, the thesis reports, there have been questions raised regarding BHT's safety. While BHT still remains a substance approved by FDA, food packagers and film manufacturers have expressed interest in alternative antioxidants. Vitamin E, also known as alpha-tocopherol (ATP), has been used for a decade as an antioxidant processing aid by the plastics industry. However, ATP's role in extending the shelf life of packaged products has been relatively uncharted territory. Ju-Fen Lin's research documents the degree to which ATP retards oxidation of a dry food product in multilayer packaging films, specifically compared to BHT. According to Dr. Jack Giacin, advisor to Lin and professor at MSU's School of Packaging, the study was funded solely by the university. Several suppliers donated packaging materials. General Mills, Minneapolis, MN, donated an oat-based cereal, and Dr. John Culter, a General Mills scientist who retired this January, also provided guidance and reviewed the project's conclusions. Two tests, three films The study compared three multilayer adhesive-laminated films. Each consisted of an ionomer/ethylene vinyl acetate copolymer coextrusion heat-seal layer, a core of high-density polyethylene, and an outer HDPE layer. The three films were identical except for the antioxidant that was incorporated into the core HDPE layer. Film I incorporated ATP, Film II added BHT and Film III, the control, had no antioxidant. One series of experiments examined how long it took the antioxidants to migrate into ambient air from 12"x12" film samples. (The slower the migration, the longer the antioxidants remain in the film.) Separate samples were stored at four temperature levels from 23°C to 50°C (73°F to 122°F). Each was measured for antioxidant loss at regular intervals over a six-month period. Result: At each of the four temperature points, ATP consistently remained in the packaging film about 10 times longer than BHT. Another series of tests measured actual product shelf life. The film was manually fabricated into several 4.5"x5" test pouches, each filled with 25 g of oat cereal, and impulse heat-sealed. Pouches were stored at 23°C (73°F) and 50% relative humidity for 11 months, with samples measured weekly for two months, then monthly. These tests measured the amount of lipid oxidation that had occurred in the cereal itself and the amount of antioxidant that remained in the packaging material. No significant difference was detected in the level of oxidation in the cereal in test pouches made from the two antioxidant films; thus, packages using ATP performed equally to those using BHT. Cereal from the control pouch, without an antioxidant, showed a marked increase in oxidation after 20 weeks, compared to Films I and II. Tests further revealed that after four weeks, no detectable levels of BHT remained in pouches made from the BHT-impregnated film. Further tests showed that 15% of the BHT had migrated into the product, continuing to provide a degree of protection against oxidation. By comparison, over 80% of the ATP remained in the film of the ATP pouches after six weeks. And after 28 weeks, almost 30% of the ATP remained in the packaging film. Measurements of the amount of ATP that migrated into the product were inconclusive. What about cost? Compared measure for measure, ATP is about three times the cost of other antioxidants, the thesis reports. However, the thesis says, ATP can be used at significantly lower levels-typically one-fourth to one-fifth-ultimately making it more cost effective. This was borne out by materials used in this study. In fact, the amount of ATP in Film I was 0.0238% by weight-about one seventh that of BHT in Film II, which was 0.157% . Predictably, officials from General Mills were not available to comment on the study or its effect on the company's future package specifications. When asked about the applicability of the results to other food products and other films, Lin told Packaging World that ATP is a candidate for any fat- or oil-rich food product where oxidation is a major concern. Specific examples cited by the thesis include crackers or potato chips, because they can easily oxidize thanks to their large surface area. MSU's Giacin agrees, saying that ATP is a packaging alternative for "snack foods, cereal products, low- to intermediate-moisture food products where fat oxidation is a concern."