TI E&PS recently became the first packager to provide Gen 2 RFID-enabled cases and pallets to Wal-Mart to meet the retailer’s mandate.

PW: Please summarize your company’s RFID program.

Shields: We bypassed Gen 1 and launched directly into Gen 2 when we began shipping Gen 2-tagged RFID-enabled cases and pallets of our scientific graphing calculators to Wal-Mart at the end of 2005. The tagging is done by our Dallas-area third party logistics provider.

PW: We understand your attention to detail extends to the logo on the RFID tag itself?

Shields: [laughs] Yes, that’s right. Our label vendor was providing the “smart tags” with the TI RFID inlays (on the back of the label) upside down. While it didn’t affect read performance one bit, I pointed that out to them and on the next order it was supplied upright. It was a minor thing, but important to us.

PW: Do you expect to get value or even payback out of your RFID program?

Shields: We want to stretch our RFID value beyond the supply chain and have identified those opportunities early on. We haven’t executed those plans yet, but there is value out there, including through reverse-logistics product returns.

PW: What do you think about item-level tagging?

Shields: This technology has to mature another two to three years before we see much item-level tagging and costs have to come down further on tags. Actually, we plan to take this to the sub-item level by working with our suppliers in tagging the technology components with RFID that will help our recycling efforts.

PW: Considerable testing was done ahead of the rollout, but how did the tests align with the real world?

Shields: You can conduct tests all you want, but it’s like a mud puddle—you really don’t know how deep it is until you step in it.

PW: How have things turned out?

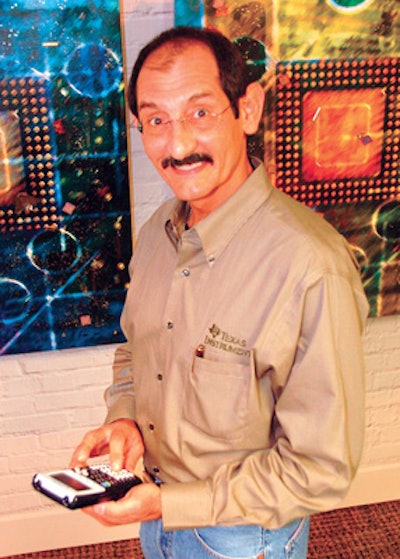

Shields: It’s been an exciting adventure. Everyone is as committed to our success as we have been, and those are the kinds of partners you want to have. —Rick Lingle