It’s easy to dismiss the science of nanotechnology as a “blue-sky” concept. After all, it’s uncertain if packaging will incorporate nanocomposite materials on a widespread basis. But ongoing developments involving nanocomposites for films, bottles, coatings, and inks demonstrate that the science is well grounded. In fact, the clay used to produce “nano-based” packaging materials is excavated from the ground.

Dig deeper into the subject of nanotechnology and you’ll uncover several instances where consumer packaged goods companies (CPGs) and packaging suppliers are exploring nanotechnology. Among them are two applications reported in the 2004 publication Nanotechnology in Packaging, written by Dr. Graham Moore, head of strategic consultancy with Pira International Ltd.

The first involves a producer of a multilayer ketchup bottle who experienced difficulties in processing ethylene vinyl alcohol as a barrier layer, which lead to an unacceptable number of bottle rejects. The bottle producer replaced the EVOH with Nanocor’s M9 material, melt-compounded in the plastic resin used to extrusion blow the bottle. This lowered rejects by 71% while maintaining the barrier properties and the same cost. The need for tie layers in the structure was also eliminated.

A March 2003 online article in Plastics Technology provided further details on the M9 nanocomposite material, noting that “through an alliance with Mitsubishi Gas Chemical, Nanocor has rights to melt compound its own nanoclay additives with MXD6 nylon for use in barrier PET bottles and films. . . . The material retains high clarity and delamination resistance equal to standard MXD6. The shelf life specified for beer in the U.S. (110 days) and Europe (180 days) can be reached with a three-layer (PET/M9/PET) structure using a thinner barrier layer than if plain MXD6 were used.” The article also mentions that Owens-Illinois and Constar Intl. are using MXD6 nylon for various food and beverage applications.

Another application reported by Moore comes from researchers at Bayer who are using nanoparticle technology in developing thin plastic films for food packaging. Only a few nanometers thick, the embedded particles prevent gases from penetrating the film and keep moisture from escaping.

Moore’s book isn’t the only source for examples of nanotechnology being applied to packaging. At Pira’s two-day international conference in late June, several other packaging developments were cited during a presentation called “Nanotechnology Today: Real Life Examples of Nano Applications.” Given by Del Stark, business development manager at the Institute of Nanotech-

nology in Stirling, Scotland, the talk cited the following packaging examples:

• Kodak is developing antimicrobials for food and medical packaging. Developed in the United States, the material is sent to the company’s laboratory in France for modification and marketing for applications in Europe. The product is available as a film or coating, with commercialization expected in 2005. Kodak is developing other active products like oxygen absorbers and biolayers for food packaging.

• Honeywell has developed a new process for the manufacture of polymer-nanoclay composites that could offer improved properties such as gas barrier. The FDA has approved them for use in pharmaceutical and food packaging, and the technology is available for license.

Specifically, Honeywell Specialty Materials/Specialty Polymers produces nylon resins marketed under the Aegis™ brand name. On its Web site, the company purports “to be one of the first companies to successfully produce these polymerized nylon 6 nanoblends.” Honeywell lists such benefits as resistance to delamination, easy processing, clarity, recyclability, and competitive cost. Three Aegis grades are available: OX is an oxygen-scavenging nylon formulated for plastic beer bottles, HFX is for hot-fill applications, and CSD is for carbonated soft drinks.

• Bayer is supplying a nanocomposite nylon film to a leading juice carton manufacturer.

• Clariant offers new pigment preparations with nano-dispersed, polymer-containing water-based pigments developed specifically for ink-jet printing.

• Poly One has developed nanocomposites and inherently conductive polymers.

Hard to define

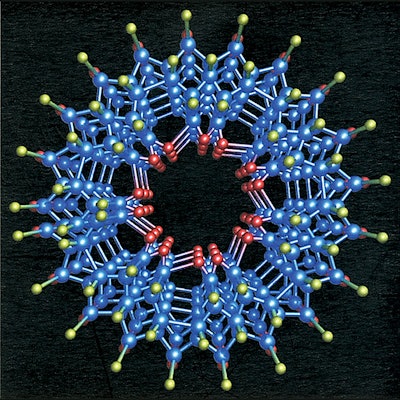

On its Web site, the Center for Responsible Nanotechnology (CRN) admits that if you ask 100 people, “What is nanotechnology,” 90 will have no idea, and 10 will offer varying definitions. The proper definition, says CRN, is as follows: “Nanotechnology is the projected ability to make things from the bottom up, using techniques and tools that are being developed today to place every atom and molecule in a desired place. If this form of molecular engineering is achieved, which seems probable, it will result in a manufacturing revolution. It also has serious economic, social, environmental, and military applications.”

In his book, Pira’s Moore explains, “Nanotechnology has been used freely in the context of describing the activities of atoms and molecules that have applications in the real world. In terms of dimensions, one nanometer is a billionth of a meter, or one thousandth of a micron.” Some have described the thickness as a small fraction of a human hair.

What’s in it for packagers?

Moore is one of three thought leaders that Packaging World contacted to discuss nanotechnology and its potential role in packaging. The others were the Institute of Nanotechnology’s Stark, and Paul Holister, technology impact consultant for Pierrelongue, in France.

Why should consumer packaged goods manufacturers be enthusiastic about nanotechnology? “I don’t know that they are enthusiastic about nanotechnology or nanocomposite materials,” says Moore. “They have needs that translate into functionality improvements, cost considerations, and so forth. They are not so interested in how [the improvements] are achieved, but [in] what is achieved, and at what cost. Barrier demands are prevalent and enhancements are likely through nanocomposites, especially in food-related [applications], but also where shelf-life storage conditions are important. The supply chain could benefit,” he says, “in material performance for the enhancement of barrier properties, and in the ability to develop further active and intelligent packaging concepts.”

Stark pointed to Nanocor, a subsidiary of Amcol Intl. Corp. “Nanocor is a world leader in the production of nanocomposites, which are polymers bonded with nanocrystals to produce the materials with enhanced properties. The company is currently producing nanocomposites for use in plastic beer bottles that give the contents a six-month shelf life. The material works by introducing nanocrystals into the plastic that essentially create a maze from which oxygen molecules find it difficult to escape. Nanocor and Southern Clay are working on improvements expected to increase shelf life up to 18 months.”

He adds, “Many applications are in the cards, such as using nanomaterials for making stronger packaging, using sensor technology in food packaging, and tagging for crime prevention.”

Gaining momentum

Holister says, “Nanotechnology will have some impact on virtually every area of human endeavor that involves materials, including packaging. In most cases this impact will be significant, if spread over some years.” He believes nanotechnology could lead to “disposable RFID tags, [bringing] value throughout the supply chain. This in turn might enhance recyclability.

“Nanotechnology is already used in packaging in the form of nanoclay composites that lower gas,” Holister continues. “However, composites based on other nanomaterials might have properties valuable for packaging applications. Properties might include improved strength, stiffness, biodegradability, chemical resistance, heat and flame resistance, and UV opacity.”

Moore says, “The development of nanocomposites for packaging applications is gaining momentum as the opportunities offered from such technology are identified and realized.” Moore cites thermal stability, mechanical strength, and improved barrier characteristics among the benefits of nanotechnology in packaging materials. Nylon films, he says, have been commercialized with improved gas-barrier properties by nanoscale additives. “Nanocomposite applications in packaging include gas and oxygen barriers, food packaging, and films,” Moore writes. He says nanotechnology has also “been applied in the development of bar codes,” which he suggests are a cheaper alternative to RFID.

Holister brings economics into the equation. “Most of the novel properties that nanotechnology can bring to materials will likely never be cost-justifiable in most packaging [such as self-cleaning coatings]. The cheap sensor applications [for detecting spoilage] seem to offer more potential in food and drink packaging.”

Who will pay?

Who will foot the bill for nanotechnology research and development that will benefit the packaging community? Moore believes the R&D will come from material manufacturers driven by the marketplace needs of packagers and retailers.

Stark, on the other hand, sees the R&D investment being made at all levels, “especially if we are looking at packaging that could be made cheaper, with better performance, and if the packaging helps with brand or quality control,” he adds.

Holister agrees that investment in nanotechnology will probably occur at all levels, depending on the particular nanotechnology application. “The nanoclay composites have, I believe, enabled the move from glass to plastic beer bottles, for example. The justification here is for resin manufacturers to move into a new market, and for packagers to reduce costs. However, the use of nanocapsules to reveal tampering or for sensors to show when food has spoiled has the greatest attraction at the downstream end of the value chain.

“Cost justification will be the major hurdle in most cases,” says Holister. “Thus, nanocomposites will in general be proven in applications outside packaging before entering the packaging sphere. Appli-cations such as disposable RFID and sensors are being researched specifically for packaging applications with the assumption that adequate cost-benefit can be achieved, but no doubt a host of other problems need to be tackled. Such applications are probably at least five years from widespread use.”

That said, nanotechnology holds promise for the future of packaging. Moore identifies potential benefits such as “the ability to use less packaging materials, but have improved properties such as barrier, and the incorporation of active and intelligent systems.”

Stark believes, “In the future there may be many exciting examples of nano-enabled systems and materials integrated into all forms of packaging. I believe there will be an explosion of new material and technologies that will impact the packaging [business].”