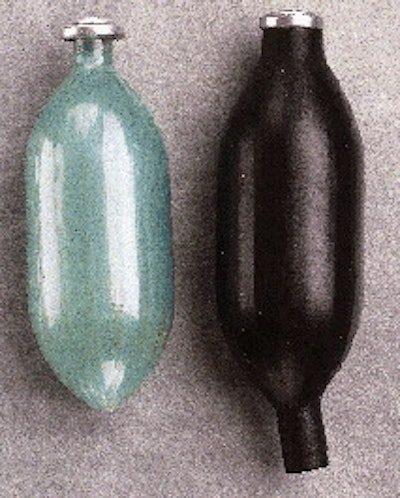

A shave gel in a plastic bottle instead of an aerosol can? To the uninitiated, it may not seem all that impressive, but as Gillette's Anne Kelly puts it, "This is quite a technical accomplishment. There's a reason why no other mass-market pressurized shave gel out there is in a plastic package." Kelly, business director for Gillette's shave preparations group, is referring to the exclusive use of metal cans for such products. Aerosol packagers have long used a propellant system-pressurized gas-that requires a metal container for product dispensing. Trouble is, a metal can isn't great for women who shave in the shower. It can rust, it's slick when wet, and if it's dropped, it can hurt toes or chip the tile or tub. To answer the need for a more shower-friendly package, Gillette has just launched a new version of its Satin Care Soft Touch Shave Gel for women in a stylish high-density polyethylene bottle. The bottle began appearing on store shelves last month alongside the venerable aerosol version, which Gillette intends to keep selling. "We'd like to have this be the premium package version," says Kelly. The 6-oz plastic package retails for $2.89, compared to the 7-oz aerosol can, which fetches $2.69. Alternative delivery method The plastic bottle, unlike the aerosol can, employs a pressurized delivery system that does not use gas propellants. Instead, it relies on an inner polyethylene terephthalate bottle, a rubber stretch sleeve and a valve, all from Exxel Container (Somerset, NJ), to dispense the gel product. At first glance, the delivery system, dubbed Atmos(TM) by Exxel, seems simple: Product is filled under pressure into a "flexible" inner PET bottle. That bottle has a rubber sleeve that's stretched tightly around it. As the user depresses the actuator, the valve opens, allowing product to be squeezed out of the bottle by the contracting rubber sleeve. While the Atmos dispensing system has been used commercially for several years, it's always been for lower-volume, high-priced cosmetics and personal care products. "This is the first time you'll see it in a product on the shelf at a place like Wal-Mart," says Kelly. It's also the first "broadly distributed mass-market [pressurized shaving product] sold in plastic," according to Kelly. Gillette declined to reveal specifics regarding the economics of this package versus aerosol cans, though Kelly hinted that the package isn't inexpensive. "High volume is our hope, frankly," Kelly tells Packaging World. A flexible rigid container? The key to the delivery system is a flexible inner PET bottle, which may seem like a contradiction in terms. Exxel starts by injection/stretch-blow-molding a bottle not unlike a soda bottle in appearance. Through Exxel's proprietary manufacturing process, a machine creates a series of vertical creases, or pleats, in the bottle as it's collapsed back to a shape resembling an injection-molded preform. These pleats allow the rigid container to become, well, flexible. "When it gets down to a certain thickness, it's flexible," explains David Groh, Gillette's mechanical development engineer for this project. The wall thickness of the inner PET bottle is 0.005". Flex-cracking isn't an issue, Groh claims. "I'm sure if you flex it enough, sooner or later it will crack," he says. "Since it's designed for a one-time use, it stands up to flexing very well." Still, PET is not known for its stretch memory retention. That's why Exxel dips the PET bottle in latex after it's pleated. Once the PET bottle is filled and expanded, the stretchable latex helps the PET bottle return to its pleated, collapsed state as the product is used up. That ensures the product is evacuated to the fullest extent. After the bottle is pleated and latex-coated, it is inserted into a rubber tube, or sleeve, that has an inner diameter-when relaxed-of only about 5/16". The tube has a wall thickness of 3/16". An aerosol-style valve is then crimped around the opening of the PET bottle. This completed subassembly, which Gillette refers to as the "power unit," is sent to Gillette's packaging facility where it's inserted into the empty HDPE bottles. It's fastened into place with a snap ring and filled under high pressure. The high pressure of the fill forces the inner PET bottle and rubber sleeve to balloon outward, swelling to a diameter of about 23/8". The actuator and overcap are then applied. According to Groh, the new package required no new equipment. "We had to buy some special filling heads, but that's the case with just about any new product," he says. Filling pressures are similar to those for aerosol containers, he says. Not as voluminous To dispense the product, the consumer simply holds down the dispenser, which allows product to escape through the valve as the rubber sleeve contracts. The velocity with which the product emerges, however, is not as great as with an aerosol package, which means the gel isn't as voluminous. "The dispensing characteristics are different," Kelly admits. "The [Atmos dispenser] doesn't exactly replicate the aerosol can. It's close, but it provides a lighter lather." Kelly also says the new product was preferred "equally" by women when compared to aerosols in focus group tests. In the end, Gillette felt the ability to provide women with a sculpted plastic container that's easy to grip, won't rust and won't damage toes or tiles if dropped outweighed any perceived difference in dispensing characteristics compared to aerosol. The package was co-designed in-house in conjunction with an outside firm that Gillette declines to identify. The outer HDPE bottle is molded by Owens-Brockway (Toledo, OH). Completing the package is a polypropylene overcap that's molded with a diagonal ridge that makes it easy to grip. Labeling challenge The gentle twist of the tapered package presented some challenges for the pressure-sensitive label, too. "Most of the decoration techniques-heat-transfer or pressure-sensitive-are really designed for a flat container," says Kelly. Groh elaborates: "This bottle tapers vertically. Because of that there's no flat surface to apply a label to. That caused us difficulty in material and adhesive selection." Sancoa (Mt. Laurel, NJ), which converts the labels, chose a more aggressive adhesive that keeps the p-s label adhered to the tapered surface. The adhesive is not water-soluble, so it resists coming off in the shower. Finally, the material selected is "more stretchable" than most, says Groh, to help it conform to the rounded bottle surface. Details on actual label structure or printing method were unavailable. Containers are labeled by Owens-Brockway prior to shipping to Gillette. Dual strategy Even though Gillette will sell both the aerosol can and the plastic package side by side, the company doesn't expect any cannibalization. Rather, it's pinning its hopes on expanding the market with this new package. Explains Kelly: "About a third of women use a shave prep, but about two-thirds shave with soap and water. Metal aerosol cans have been one of the barriers to getting soap-and-water shavers into using a prep product. They're just not great in the shower. Our new bottle makes shaving easier with its soft curve shape that won't slip out of a woman's hand."