If syngas is the key to packaging sustainability, why haven’t you heard of it? Why isn’t syngas part of your company’s sustainability strategy? Syngas may offer the closest thing to the perfect path for robust, truly circular, chemical recycling. What is syngas? Syngas is primarily a mixture of carbon monoxide and hydrogen, the reactive building blocks of virtually all plastic packaging materials. More importantly, syngas can be readily made from unsorted mixtures of plastic packaging waste using the well-established process of gasification. Pyrolysis is a thermal cousin to gasification, which also produces some syngas, but in lesser quantities, as pyrolysis favors production of char (e.g., charcoal is made by pyrolyzing wood) and a liquid hydrocarbon stew known as pyrolysis oil. Gasification primarily produces syngas.

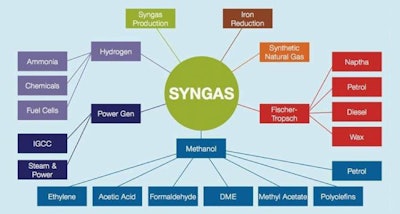

During World War II, as Germany struggled to maintain petroleum supplies, it turned to coal gasification to produce syngas, from which liquid hydrocarbon fuels were made to support the war effort. Comparing the constituents of coal to packaging plastics (e.g., PET, polyethylene, polypropylene, polystyrene, polyamide, etc.), we find mostly the same elements, namely carbon, hydrogen, oxygen, and nitrogen. It is no surprise that gasification of coal and waste plastics (and paper and virtually all organic chemicals and materials) leads to the same valuable product: syngas. As shown in Figure 1, syngas is used commercially to make much more than hydrocarbon fuels.

Many chemical companies throughout the world produce syngas to make a variety of valuable chemicals. Figure 2 shows a map of locations of syngas production facilities that currently serve the global chemical industry. It is only a matter of demand for chemical companies to produce plastic monomers from syngas. It is only a matter of knowledge and will to transform our waste handling system into a robust syngas producer.

Consumer Packaged Goods brand owners are making pledges to deliver 100% recyclable or reusable packaging by 2025 without a clear path to achieving that goal. Their packaging suppliers, especially flexible film converters, are unsure whether they will be able to satisfy their customer demands without sacrificing quality or significant portions of their businesses. The beauty of syngas is that all of today’s plastic packaging is already 100% recyclable through this syngas pathway. What is missing is not new packaging, but rather the waste handling infrastructure to convert waste to syngas.

Importantly, even NGO’s with an interest in packaging sustainability recognize the value that robust chemical recycling such as gasification offers for achieving real circular economy sustainability. The Ellen McArthur Foundation published a white paper titled, “Enabling a circular economy for chemicals with the mass balance approach.” This approach offers the opportunity to certify recycled content of materials produced, in all or in part, from waste-derived syngas. Therefore, to achieve 2025 pledged goals, there is no need to change packaging materials or structures. What is needed is a transformation in how we view waste handling and recycling.

It is not surprising that society’s reliance on consumer cooperation to selectively sort waste, duplicate collection of recyclables and trash, mechanical recycling, landfilling, and/or exporting waste has failed. The current waste handling paradigm is too complex, expensive, and ineffective, as evidenced by so much of the waste floating in the oceans. Until now, we have successfully hidden or shifted the burden of this failure. It is now time to get serious about fixing it. It behooves all packaging industry stakeholders to do what is needed to ensure that the coming transformation solves problems for which the packaging industry is being blamed without needlessly destroying the packaging industry. Conversion of packaging waste to syngas represents the most robust and flexible path to circular economy sustainability.

While pyrolysis and traditional gasification offer benefits, they both require a good degree of sorting in order to eliminate certain materials from the waste stream. A variant of gasification, known as plasma (assisted) gasification offers the greatest benefits for waste handling. Plasma-assisted gasification can achieve high process temperatures using electricity and without using feedstock as fuel, as is typically done with coal gasification and pyrolysis. Since waste is much more variable than coal, high temperatures make the process even more robust since it can treat virtually any earthy material found in municipal solid waste, without being sorted. Plasma gasification is so robust that it is used to convert hazardous chemical wastes, including (waste-to-energy) incinerator ash, chemical weapons, and biological wastes.

Metals and minerals are literally melted down, and organic materials are converted to syngas. Molten metals and mineral oxides are recovered in a manner similar to the metals industry, as ingots and “slag.” The term slag is borrowed from the metals industry to refer to the lighter mineral oxides that separate from metal to form a vitrified, glassy rock or products useful in a variety of applications such as construction aggregate, abrasives, and glass fiber insulation. Therefore, even those currently non-recyclable multilayer flexible films, incorporating papers and foils (e.g., Tetra Pak and SIG Combibloc aseptic cartons, coffee bags, blister packaging, etc.) are already 100% recyclable and recoverable using proper waste treatment methods.

Neither gasification nor plasma-assisted gasification is incineration. Like most useful feedstocks such as wood and petroleum, syngas can also be used as fuel to produce energy. When possible, however, it is preferable to produce more valuable material products. Therefore, gasification is properly referred to as waste-to-syngas as opposed to waste-to-energy, which is just one possible use for syngas. When used for energy, however, syngas is remarkably clean.

As plastics are increasingly sourced from renewables, such as plants and algae, energy derived from subsequently produced syngas becomes increasingly zero net carbon, since plastics produced from plants are effectively biomass, and biomass energy is renewable and zero-net-carbon sustainable.

Therefore, syngas offers the packaging industry at least two truly circular sustainable paths:

1. Plastic to Packaging to Syngas to Plastic

2. Plants to Plastic to Packaging to Syngas to Energy to Plants