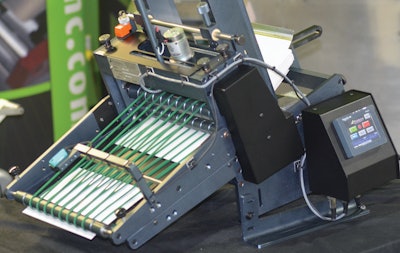

Pineberry Manufacturing Inc. makes friction feeders that insert coupons, paperboard inserts, envelopes, cards, etc. The firm claims to have the only open-source feeders in the marketplace, which means proprietary electrical components have been eliminated. Pineberry Manufacturing’s HSF and SF Series friction feeders, says the firm, are characterized by an unmatched level of operational simplicity, reliability, robustness, and cost efficiency. Also, they can be easily integrated into manual or automated lines. The HSF operates at 8,000 inches/min and the SF at 3,000.

“Our friction feeders are open-source, servo-controlled power platforms with a Schneider Electric PLC touchscreen controller, reducing the overall number of components to the machine,” says Pineberry Manufacturing President David McCharles. “Users can get information from the terminal remotely through an app on a smart phone. Open-source technology is the way the future is being built.”

The PLC controller itself has replaced proprietary control boards. All the parameters that were only accessible through a PC or laptop are now also displayed on a simple PLC terminal. It’s a smarter machine, but overall it’s a simple machine to use, claims Pineberry Manufacturing. The feeders with their Schneider Electric touchscreen controls provide the operator with ease-of-use and full availability of real-time machine performance data.

Also supplied by Schneider Electric are the two servo motors on these friction feeders. One motor governs the belt that drives items through and the other actuates the nip roller that is commonly found on friction feeders.

McCharles says that until early this year, Pineberry Manufacturing followed the practice of its peers and competitors by making friction feeders as well as the microprocessor controllers that governed them. “If something goes wrong, they had to send the controller back for us to fix it,” says McCharles. “Now that’s no longer the case. Open source means we give customers a program and if they want to make changes or integrate with other machines, it’s really easy. Or, if for any reason we’re unable to go to their plant should support be needed, we can support them remotely. This technology is the way the future is being built.”