This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

As COVID-19 has impacted many industries, Morrison evolved to overcome the new challenges posed. With Morrison’s company focus always being on innovative container handling solutions, adapting to the challenges posed by new COVID-19 health and safety regulations has been a smooth transition.

Featured products at this year’s PACK EXPO include the Morrison Auto Adjust Rails, Rapid Change Parts, Morrison’s slave driven system, and our COVID-19 Test Kit Integrated System.

Morrison’s demo schedule is:

Retrofits + Upgrades Making Your Current Machinery Work for You—Monday, November 9th at 12:45 p.m. CT

Efficiency is key on any manufacturing line. An easy way to increase your efficiency is through upgrades and retrofits to machines your company already has. Over half of Morrison’s custom drive assemblies are built to fit into existing production lines. Want to see how this could work for your company? In this two part demo series explore the possibilities Morrison can provide to enhance the system you already have. Learn all about Morrison’s top solutions: slave driven systems, stars and guides, and our ability to mount our solutions to existing conveyors. Don’t let your current lines inhibit the production goals you can accomplish.

Pharmaceutical Container Handling: Morrison’s Innovative Approach to Efficiency—Monday, November 9th at 2:30 p.m. CT

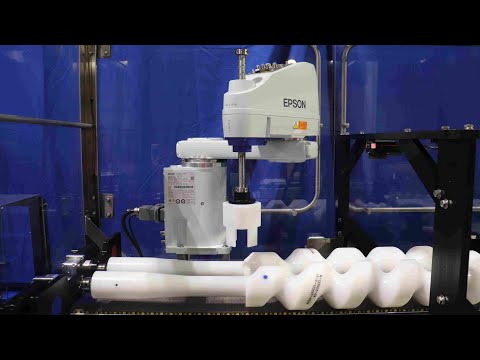

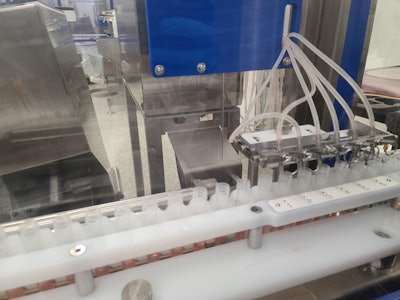

Morrison is experienced in handling a variety of pharmaceutical containers. Whether it be vials, blister packs, syringes, ampoules, or sachets, Morrison can develop the container handling solution specifically for your companies needs. Smaller product sizes like pharmaceutical containers require more precise handling procedures and sanitary regulations. That’s why Morrison’s approach of custom designing parts for each project is ideal for improving your current system, or fully integrating your packaging process. These products are vital to keeping our community safe, so let Morrison help you improve your process and maximize your potential. Cases We’ll Explore: COVID-19 Test Kit Integrated System, Ampoule Twisting, and Syringe Orienting.

Need Variety? Building Efficiency with Morrison’s Denest, Stack and Sort Solutions—Thursday, November 12th at 12:30 p.m. CT

Efficiency is high priority in all production lines. Whatever the challenge, Morrison’s team of engineers is ready to develop a solution for it. Morrison’s commitment to innovation can be the thing that takes your manufacturing line to the next level. Need to stack, denest, and sort your products? Morrison’s container handling experts are ready to find you the solution best fit for your company. If multipacks are running on your line, Morrison solutions should be too.

Quick Changeovers: Minimizing Downtime with Morrison Stars and Guides—Thursday, November 12th at 2:15 p.m. CT

When it comes to rotary equipment, Morrison is the top choice for many. OEM partners among others go with Morrison as their go-to change parts producer. Morrison’s capabilities to retrofit their products onto your companies existing machinery while still committing to tight tolerances is what makes Morrison leaders in the change parts industry. Commitment to Support Built In® from installation through start up also makes Morrison stand out.

Tackling Your Toughest Packaging Challenges with Morrison’s Customized Solutions—Thursday, November 12th at 2:45 p.m. CT

Unique challenges require unique solutions. Morrison’s custom design capabilities can be the solution your company needs to improve your packaging line. Our engineers can design a custom solution, fit for your container specifically for whatever packaging application you may need. Having worked with budgets as small as $5000 to as large as $1 million, no project is too big or small for the team at Morrison.

Timing Screw Expertise: Morrison’s Nearly 50 Years of Timing Screw Magic—Friday, November 13th at 10:30 a.m. CT

Coming up on 50 years in the container handling industry, Morrison’s years of expertise make them the company to choose when it comes to timing screws. Split second accuracy is essential for efficient container handling, making timing screws one of the most important elements on any packaging line. Explore what nearly 50 years of our dedication to science of timing screws can do for your production.

Infinite Adjustability at the Push of a Button: Morrison’s Auto Adjust Rails—Friday, November 13th at 12:00 p.m. CT

Infinite adjustments are just an order away with Morrison’s Auto Adjust Rails®. Discover how installing Auto Adjust Rails® allows you to perform changeovers with the push of a button, saving you wasted time and resources. With two styles, the rails come within 1mm of accuracy for individual bottles and 5mm of accuracy for case handling. See how this user friendly, easy to retrofit technology can improve your manufacturing line efficiency.

Visit Morrison’s showroom at https://pe.show/165.