The nature of work, especially in manufacturing, has evolved more rapidly than the way that we think about work. And the ways that we prepare (educate) people for work have not kept pace with our changing needs. A work-based learning model, coupled with high school, community college and university education, is a technique that has delivered considerable success in meeting the demand for skilled workers for manufacturers and others. Becoming involved in work-based learning initiatives is a useful and perhaps necessary strategy for manufacturers to employ if they hope to ensure the availability of the next generation of skilled workers that will be required to sustain and grow business.

Work-based learning encompasses a variety of programs that we have called apprenticeships, internships, co-ops, and externships. What all of these programs have in common is that they combine practical, hands-on work experience with both theoretical and practical classroom learning. Where the programs differ is in the formal relationships between the student, the employer, and the school. Each term also carries some pre-conceived but not necessarily correct notions that can get in the way of moving forward to real and useful outcomes. For all of these programs, the best results are obtained when there is true collaboration among the parties so that the students, educators and employers all win.

In the U.S., we have made two drastically wrong turns in setting educational policy. The first wrong turn was taken immediately after World War II when we opted to take higher education on a single track focusing on theoretical studies rather than on a dual track with one of these tracks focused on applied technology. That direction was taken contrary to the recommendations of experts who had studied the issue and contrary to what was done in much of the rest of the educated world. The mistake was not immediately apparent since the returning GIs that flooded into our colleges and universities already had “practical experience” from rural America and the war. The second wrong turn was made after the Viet Nam War, during which time student military draft deferments artificially drove both demand and capacity for Bachelor and advanced degrees. At the conclusion of the war, to continue to fill that capacity and the perceived need for advanced degrees, we embarked upon removing practical education from our high schools and promoted the false narrative that a “university education was important for all.” The fact remains now as then, that for every 10 jobs in our economy, only 1 requires an advanced degree, 2 require a university degree, and 7 require a high school diploma, a one-year certificate, or a two-year community college degree. (For corroborating references, see Manufacturing Workforce Development Playbook)

Both of these wrong turns have contributed to our moving further and further away from work-based learning models, resulting in the shortfall of skilled workers for manufacturing and other technical occupations in operations, design & construction, and research & development. The United States Department of Labor (DOL) claims that there are 5.5 million unfilled jobs currently available, largely in the technology sectors. The National Association of Manufacturers and Deloitte Consulting say that there will be a shortfall of over 2 million technically skilled workers for manufacturing jobs over the next decade. This is why DOL and other government entities are investing billions of dollars into training programs that are tied to work-based learning. But parents and students are not yet getting the message. Students should be counseled that if they pick an educational pathway that leads to an in-demand job, and couple that with work-based learning, they can graduate from college free of debt and with job offers already in hand.

Confusion over terms

We most often discuss work-based learning using the term “apprenticeship.” But many of today’s work-based learning opportunities are better termed “internships.” An apprenticeship is an arrangement whereby the individual is an employee first and a student second. A company first hires the person, usually on a full-time basis. He or she is then enrolled into an apprenticeship program and put under the supervision of a journey-level craftsperson or trade professional. While obtaining hands-on experience, the apprentice is also enrolled in classes that may be taught at work or in a local school.

Apprenticeship has a long history, growing out of occupations that required extensive practice at hand-eye coordination to perform tasks such as stone cutting, filing, lapping, and typesetting. As such, apprenticeship is usually associated with blue-collar jobs. But in prior times when books were both exceedingly rare and expensive, even occupations such as lawyers were apprenticed so that the student could gain access to the books that were owned by the journeyman. This is where the term “reading the law” comes from.

Today’s formal apprenticeships may be registered or unregistered. A registered apprenticeship is one in which the U.S. Department of Labor, or a similar entity at the state level, approves the requirements for the apprenticeship and oversees, to varying degrees, its administration. Registered apprenticeships may be operated by a labor union, a single company or a group of companies. Those completing a registered apprenticeship receive credentials that are truly transportable from place to place and employer to employer, a feature that works especially well for construction trades. But here is where we see the term “apprenticeship” starting to bring some unfavorable connotations, especially with small business owners who want neither the government nor a union involved with their training and development program, nor do they view their workers as apprenticing for blue collar jobs.

An internship is an arrangement whereby the individual is a student first and an employee second. A student enrolls in an educational program, often on a full time basis, and then obtains employment related closely to his program of study, usually with assistance from the school that may have employers lined up at the door seeking qualified candidates. The employment may be part time, running concurrently with the class schedule, or it may be full time during certain periods, alternating between work and study on a semester by semester basis. Internships are normally administered by the school in cooperation with employers. If working towards a degree, the student will get his or her general education requirements and job-related theory at school and hands-on or practical experience on the job. The best programs will provide both theory and hands-on practice at school, enabling the students to be immediately productive while receiving their on-the-job training. Internship is well suited to the types of jobs people prepare for today, jobs that have significant amounts of technology content.

Incorrect belief

The negative connotations associated with the term “internship” start from the incorrect belief that internships involve work for no pay. While some internships are unpaid, federal law has strict guidelines that prohibit most unpaid internships. Internships with manufacturers and other tech-savvy companies often pay very well, using a sliding scale that is based on a percentage of starting wages for that occupation and the percentage of the intern’s completed education. Internships are also frequently associated only with white-collar jobs. This too is a misconception, with many internships being offered today for technicians and factory workers. The term “gold-collar jobs” has arisen in the workforce world to describe those jobs that require individuals to use their hands, their minds, and their special local knowledge, making these workers worth their weight in gold to their employers.

Apprenticeships have historically been time-based, taking typically up to four years to complete. Recently, competency-based apprenticeships have been catching on for both registered and unregistered apprenticeships. A competency-based apprenticeship looks a bit more like an internship, because it involves testing similar to that found in a college educational program. A competency-based apprenticeship may be adapted to the needs and speeds of both the employer and the student. In our rapidly changing world, driven by Moore’s law of semiconductor proliferation, 4 years is a long time, and skills need to be constantly updated.

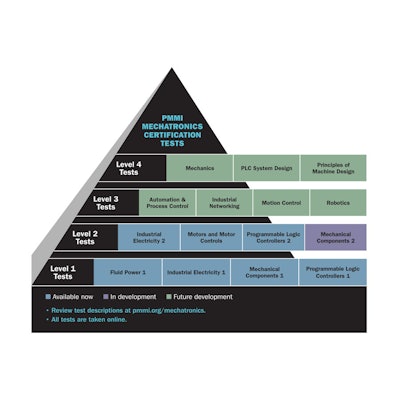

Internships are more frequently associated with college degrees than are apprenticeships. The technical content of both may be identical, but apprenticeship programs will not generally include the general education requirements of history, art, language, and so on that an associate or more advanced degree will require. Employers, however, are coming to value the well-roundedness that a degree brings, even for the shop floor operatives, and some schools are able to transfer apprenticeship programs directly to college credit. What both apprenticeships and internships often do include are industry certifications. Industry certifications are now required by law to be part of government-funded training programs that do not lead directly to a college degree. For example, PMMI—The Association for Packaging and Processing Technologies, offers certifications in Mechatronics and Industrial Maintenance that are recognized by both the U.S. Department of Labor and the National Association of Manufacturers. Eight of an eventual 15-20 certification exams have been completed. These exams are arranged in 4 tiers corresponding to the rungs of an occupational career ladder. Completion of 12 of these exams is the equivalent of a robust 2 year degree program in mechatronics engineering technology, and completion of all of the certifications would correspond to the technical content of a similar Bachelor’s of Technology Degree. PMMI also has a competency-based apprenticeship guideline that maps directly to these certifications. This guideline has been approved by the U.S. DOL and may therefore be used for either registered or unregistered, competency-based apprenticeship programs. An important lesson from recent changes in federal law is that employers must recognize, use and support industry certifications if they expect our school systems to be able to obtain government assistance to build the costly and rapidly changing infrastructure that is a requirement for good technology education.

Likewise, educators must become more comfortable with work-based education. As I have worked to bring educators, government, and industry together on this problem, the imprinted meanings of the terms “apprenticeship” and “internship” that have been discussed above can and do become an obstacle to understanding and cooperation. We often hear that the U.S. must implement the “German apprenticeship model.” But according to my German colleagues and my own investigation, that model is actually an internship model that has been incorrectly translated into English. Additional evidence for this comes from a U.S. executive of a global packaging company who commented that their Italian plant “has a very robust internship program, but the Italians call it apprenticeship.” Even though outcomes can be very similar, confusion and push-back result from the individual and corporate biases that arise from the connotations associated with the language that we use.

Regardless of what we call it, some Consumer Packaged Goods companies are keenly aware of how important it is to interest the next generation in the business of making things, and they do so by offering work-based learning experiences. Sparks, MD-based McCormick & Co., a 126-year-old maker of herbs and spices, is one of them.

“It’s a major focus of ours,” says McCormick’s Michael Okoroafor, Vice President, Global Packaging Innovation. “If you look at the technical side of manufacturing, what you see is that most people in the U.S. are avoiding it as a career choice. It’s no secret. That’s why the government is spending a lot on STEM initiatives—Science, Technology, Engineering, and Math. They realize that the U.S. has been losing ground in these areas. The best way to reverse that is to make sure that you bring theyounger generation into the innovation field, because I can tell you that I am genuinely excited about some of the innovative new things we’re doing. When young people see that, that’s howyou notonly bring them into manufacturing but retain them, as well.

“We have an aggressive internship program that is targeted not just at showing young people what we do but mentoring them along the way so that they will be inclined to stay with the company. We’re thinking about the future generation, and we’re meeting with significant success. We also sponsor research in the universities. Guess who works with the university professors on the research? The students, of course. So by the time they graduate, they’ve already been exposed to our company and have a sense of the interesting things we make.”

Leading educators are also on board the work-based learning bandwagon. Cheryl Garrison accepted the David A. Harvey Memorial Scholarship on behalf of Tri-County Technical College in Pendleton, South Carolina at The Automation Conference 2014. This award is presented by Packaging World and its sister publications for educational excellence and went to TCTC largely in recognition of their outstanding work-based learning programs. Garrison says, “ The growing demand for high tech careers has necessitated that the college employ new and different ways of collaborating with local business and industry to meet this need. At our college, work-based learning is the umbrella term used for apprenticeships, co-ops, and internships.”

In less than three years, Garrison and TCTC grew their work-based learning participation from 6 companies and 20 students to 40 companies and over 130 students. TCTC is a participant with PMMI in developing and applying the Mechatronics Certification Program and has described their success with companies such as Michelin, BMW, and Bosch in chapter 25 of the Second Edition of The Manufacturing Workforce Development Playbook. To learn more about these and other work-based learning strategies—and about how industry, government and education can work together to prepare for a renaissance to sustain manufacturing in America—download the playbook at www.packworld.com/workforce.