Robert Muehlfellner had never addressed a PMMI audience before, and he came bearing a significant gift for his first, the annual Safety Conference. The senior technologist for B&R Industrial Automation announced that the company was offering its safety network technology to the industry.

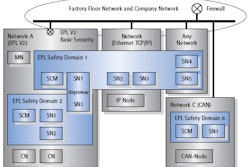

In fact, Muehlfellner showed that the openSAFETY protocol, part of IEC 61784-3, has already been implemented successfully on the popular Modbus TCP and EtherNet/IP networks. Combined with the POWERLINK standard that B&R originally developed, these three account for some 63% of installed industrial Ethernet networks. The POWERLINK standard, covered under IEC 61158, is the only real-time solution based on standard Ethernet hardware and software.

The openSAFETY standard has also been implemented on SERCOS III.

At the end of this article you’ll be asked to participate in a poll. Why should you care?

Why take a software product developed at substantial cost and give it away?

Because it’s both the right thing and the smart thing to do.

Openness spurs adoption of important new technologies. Standardization prevents having many ‘flavors’ of a technology in the marketplace that are costly to support and cause specifiers to take a ‘wait and see’ attitude until one standard prevails.

Anyone who’s been in automation long enough will recall the so-called field bus wars of the 1990’s. First, there was a standards-based initiative to create SP 50, or Foundation Fieldbus, as a universal network in the process industries. That caused automation suppliers who’d enjoyed the monopoly of their proprietary networks to push for their own ‘standards.’

In the end, installed base and marketing resources won out over standards or technology. A number of highly regarded bus technologies – such as Smart Distributed System, LONworks and Interbus – faded from the industrial automation market after being simply outspent.

By the time that industry began to move to Ethernet-based industrial networks, the market shares were largely fixed, with a few notable exceptions. First, one of the original industrial Ethernet protocols, Modbus TCP, was folded into the Open DeviceNet Vendors Association where it now coexists with EtherNet/IP developed by Rockwell Automation. Siemens migrated its Profibus to Profinet. SERCOS IGS has also migrated its fiber-optic SERCOS II to Ethernet. Other notable Ethernet based networks with strong followings in the Western marketplace are B&R’s POWERLINK and Beckhoff’s EtherCAT.

It’s too late for one Ethernet – but not for one Safety

It’s too late for one industrial Ethernet that has the determinism to support logic and motion. That boat has sailed and we’ve all learned to live with ‘flavors.’ The standard Ethernet TCP/IP and UDP protocols are fine for non-time sensitive communications, but not for networks that must be updated in the millisecond to hundreds of microseconds range.

So, in the first public venue in North America, B&R did the right thing. They’re offering the marketplace a choice that it’s never had – by sharing their intellectual property for use on competitive networks. And they’ve already proved it works.

Why, then, would any OEM or packager want to learn a different safety protocol for every network they already support? It wouldn’t make any sense, especially at such an early stage in market adoption for safety networking, and especially since this standardization doesn’t make them change their installed base. This also makes it somewhat easier to adopt a different industrial network in the future -- at least it wouldn’t mean adopting a new safety protocol.

Safety is one of the biggest areas of upcoming industrial network investment, so this is a place where standards matter most right now. Safety networks and processors are replacing hard wired safety connections – just as field buses did for control systems -- providing greater diagnostic capabilities at reduced installed cost.

Of course, B&R management recognizes the opportunity this presents to increase its stature in the industrial automation market worldwide – because the open safety protocol applies not just to North America, but to Europe and the growth markets of Asia and India, and the emerging markets of Latin America and Africa. For multinationals dealing with different regional standards, this is a very big deal.

And the open safety protocol isn’t just for Ethernet based networks, it can be implemented on the application layer of legacy networks, such as DeviceNet.

If you want open safety networks, speak up today

In technology adoption, there is always a limited window of opportunity to create standards – specifically, that’s before commercial interests override the common good.

In reaction to openSAFETY, is it possible that other safety protocols will suddenly be open sourced, confusing the marketplace and slowing adoption? Absolutely.

Or that, if users do nothing, the status quo will prevail and the opportunity be missed? Again, absolutely. Inaction allows the status quo to prevail.

So, let’s start by taking a poll. Click here to vote yes for standardizing on openSAFETY. Click here to vote no. Voting requires registration on packworld.com to prevent multiple balloting. Your information will not be disclosed unless you indicate that you want to demonstrate your public support for standardization.

What’s next? If you are really serious about taking control over the destiny of your safety functions, contact the Ethernet POWERLINK Standardization Group and let them know you will support them as they lobby for standardization.