While the data in the charts shown here are valuable without much explanation, Packaging World editors thought some commentary would help readers tease out the implications that lurk behind the numbers. So we sent the survey results to Ken Ryan and Keith Campbell and asked them to comment. Ryan is director of the Center for Automation and Motion Control at Alexandria Technical College in Alexandria, MN. Campbell, formerly the executive director of the OMAC Packaging Workgroup, now runs Campbell Management Services and is active in packaging education initiatives in Pennsylvania.

The results illustrated in Chart 3 caught Ryan’s eye.

“It’s very telling,” says Ryan, “that real-time, PC-based machine control was ranked most important by so many respondents, particularly when the respondents are all end users. And look what ranked second: shop-floor-to-top-floor integration. Both of these emergent technologies are fundamentally about real-time sharing of information. You’d expect such a response if the respondents were manufacturers of automation technology, but I think it’s significant that so many end-users would rank it so high.”

Ryan also finds it interesting how many respondents said that a standardized operator interface with a common look and feel was important to their packaging operations.

“This is something that some end users have been trying to get the OMAC Packaging Workgroup to pay more attention to,” says Ryan. “True interoperability across controls platforms that come from competing suppliers of automation technology may never come about. But if 80% of their code is transportable, then when an operator/technician moves from one company to another, if the controls system is not from the same vendor, at least it will have the same look and feel. Troubleshooting gets a whole lot easier when the operator interface has a common look and feel across a range of controllers made by different suppliers.”

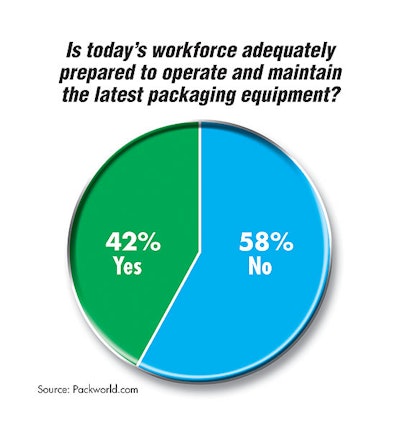

Campbell says the survey response that surprised him is the one illustrated in Chart 1.

“Can you imagine if 58% of pilots, nurses, barbers, or carpenters were judged as unable to do their jobs?” says Campbell.

He believes the results shown in Chart 2 reflect poorly on the educational institutions whose job it is to train workers about packaging and packaging equipment. “Only 20% of respondents think their schools are doing a really good job of educating students on what is needed to maintain packaging equipment.”