As packagers cope with an increasingly segmented marketplace, one of the fastest-growing techniques to meet that demand has been the employment of contract packagers. When retailers make “speed-to-market” a top priority, manufacturers find that outsourcing of packaging can be the quickest way to compete. It’s not always the least expensive, of course, but it can pay for itself through increased sales. These are just some of the conclusions that have been drawn from an in-depth research project on contract packaging undertaken by Packaging World last fall. Not only were three separate surveys on contract packaging conducted on PW’s Web site, Packworld.com, but additional interviews were conducted with representatives of both contract packagers and the companies that hire them. This overview will discuss the emerging trends in general. In addition, PW will present the findings of its end-user survey. This special report also includes a piece by assistant editor Abbey Lewis-Reinholdt on what contract packagers themselves are saying about emerging trends in the marketplace. The results of a survey of suppliers that sell to contract packagers will be presented next month. Understanding contract packaging is a little like dancing with a ghost. You know it’s there, but it’s almost impossible to get your arms around it. And it’s known by many names: co-packing, contract manufacturing, repackaging, co-packaging, and fulfillment. Although each of those terms represents some specific activities (see “The Analyst,” PW, Aug. ’01, p. 119), the differences are regularly overlooked by many packaging people. In essence, these terms are used almost interchangeably by people in industry. For example, a packaging executive for a major national food processor claimed in a conversation that his company used more than 100 individual co-packers around the country. When the term co-packer was questioned, he admitted that many of those companies didn’t qualify as co-packers, but that his company used that term to denote all companies that did packaging for them. Regardless of the term a company uses, all involve outsourcing of the packaging function. And outsourcing, another broader term that includes contract packaging, is said to be growing at 15%/yr, according to The Outsourcing Institute, Jericho, NY. Once the exclusive province of large companies, outsourcing is now experiencing its greatest growth from smaller companies, those with $10 to $15 million in sales, according to Frank Casale of the Outsourcing Institute.

Reasons to outsource As the end-user survey points out, there are several primary reasons a company looks to outsource the packaging function. Although end-user participants said that “technology not available in-house” is a major one, the CPs that participated in the survey don’t heavily sell that benefit. Nearly a third of CPs said that “speed-to-market” was the advantage they promote most to end users. Some companies recognize that CPs can replace, either temporarily or permanently, the approval processes for getting a plant and packaging lines set up and operating. But the unavailability of labor skills at the end user is also a strong factor and the second-most-promoted benefit by CPs at 27.5%. Companies that outsource packaging typically pay only for the labor they need, when they need it, thereby eliminating the cost of keeping those employees year-round. This advantage was once tied to the union vs nonunion debate, but this is no longer quite so important. Some CPs are organized, but often their labor rates are substantially lower than many manufacturers. In addition, minimizing capital investment is a strong issue for end users, but it’s only considered the primary benefit by 15% of CPs. “A processor making a new product has got to think long and hard about whether to build a new plant, buy all of the equipment, and hire workers to operate it,” one packager explained. Finally, logistics and distribution can also be a primary reason to use a CP. Better geographic location was promoted as the primary benefit by 10% of CPs that participated in the survey.

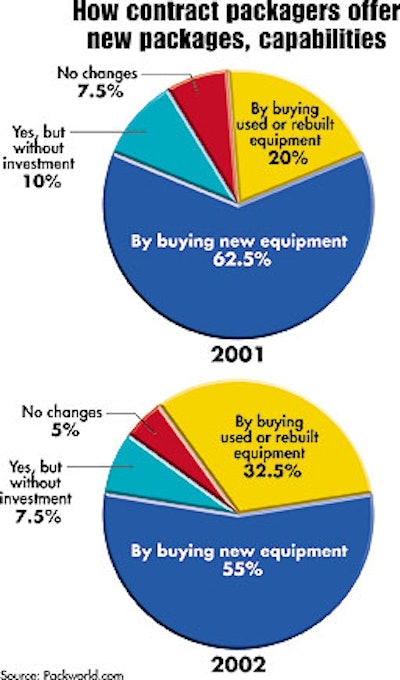

Bullish and investing more The contract packagers studied are very bullish about their business. About 60% said their business was up last year, and 87.5% say they expect sales to increase this year. In 2001, some 65% of CPs reported a larger roster of clients. More than 92% of the CPs participating in the survey said that their companies had offered new package styles or capabilities to its customers last year, and the majority did it by buying new equipment (see Chart). A smaller, but significant number of CPs expanded their capabilities by buying used or rebuilt equipment last year. Much the same is expected for this year, respondents reported. However, the CPs reported that more companies will extend their capabilities through used or rebuilt equipment. Nonetheless, nearly two-thirds of the CPs will be buying new equipment this year. And, although 82% of CPs said their companies bought equipment in 2001, nearly 87% expect their companies to make capital purchases this year. Finally, the survey asked CPs to rank their equipment, from very basic to state-of-the art. While nearly 18% of respondents said their plants have basic or very basic equipment, more than 37% of respondents said their plants are modern or state-of-the-art. If that characterization seems surprising for contract packagers, consider the fact that these companies have also been affected by the tight labor market. A CP specializing in household products represented many others when he said: “We are leaning towards automation because productive workers are hard to find.” A co-packer of frozen foods said: “We look for more automation to fill a labor shortage problem.” All of these survey results point to a dramatic new picture of outsourced packaging. The contract packager of old—low to moderate automation with lots of workers—has given way to new, more modern operations. In fact, many of these CPs may be the equal of—or even superior to—the packaging lines operated by their manufacturing clients.