This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

In this process, the starting material (used plastic) is first collected and shredded, then its ingredients are analyzed. Next, undesirable foreign substances are filtered out, and the material is dried. By renewed agglomeration, a starting material is created in the form of a granulate.

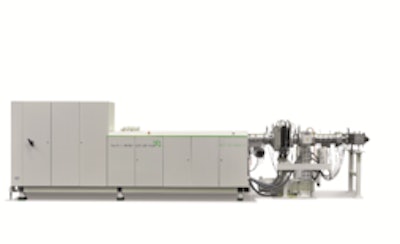

This granulate is melted by high-speed extruders from battenfeld-cincinnati and degassed via vacuum zones. In this way, volatile foreign substances are extracted and pumped off separately. The high-speed extruder is particularly well suited for this purpose, since its compact design in combination with a powerful transmission drive ensures a high output. These two advantages were decisive factors in the design of the entire system. An additional benefit is this extruder model’s user and maintenance friendliness. battenfeld-cincinnati specially developed a new processing unit and screw geometry for this application.

Downstream reactor units then split up the melt delivered by the extruder into its individual components.