This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Automation machinery company Morrison Container Handling Solutions is gearing up to unveil two new machines at PACK EXPO Las Vegas this September in Booth W-3522—a re-envisioned Screw Denester and Robotic Orienting System. The show will mark a new era for the organization, highlighting a transition to robotics rooted in screw technology for continuous motion solutions.

In addition, the company will be showcasing a variety of other container handling machines.

“For over 54 years, Morrison has led the industry in continuous motion timing screw solutions, bringing automation to both simple and complex container handling challenges,” said Nancy Wilson, CEO of Morrison Container Handling Solutions. “We’ve always believed that the best technology is the kind that empowers our customers to be more efficient. With the introduction of our new Screw Denester and Robotic Orienting System, we’re proud to continue that legacy—delivering innovative solutions that build on the trusted timing screw technology our customers already rely on.”

Smarter Denesting with Morrison’s Screw Denester

- Continuous motion denesting for maximum throughput

- Quick change timing screw cartridges for adaptable, tool-less container changes

- Compact footprint ideal for tight spaces and seamless integration

- Reduced maintenance and mechanical wear, improving long-term reliability

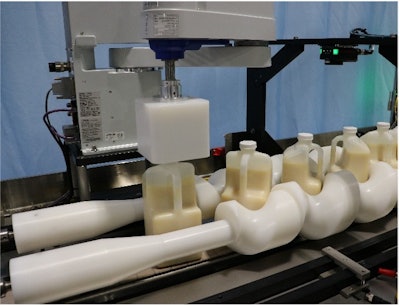

Whether used upstream of a filling operation or integrated with other Morrison solutions, this new standard, Screw Denester enables consistent product handling and speeds changeover without manual intervention.

At the show, Morrison will also showcase its legacy, custom denesting solutions that fulfill more complex customer needs.

Introducing the Robotic Orienting System: Flexibility Meets Precision

Morrison’s new Robotic Orienting System combines the agility of robotics with Morrison’s deep expertise in timing screw container manipulation. Designed for packages that require orientation based on shape, label position, or closure alignment, this system provides:

- Advanced vision integration to identify and orient containers in real time

- Scalable, high-speed throughput using parallel robotic arms

- Adaptability for multiple container shapes and sizes, with change parts

- Smart control systems for recipe-driven changeovers

This new approach to container orientation provides flexibility as SKU complexity increases. Unlike competitive models on the market, this approach uses timing screws to maintain positive control of the container, giving manufacturers a better option to maintain container control.

More on the Show Floor: Container Handling Inspiration

Morrison is known for having multiple pieces of equipment on the floor that serve as inspiration to the ways in which the company manipulates and positions containers. This year, attendees with find:

· Combiner and Divider Loop: Learn about simple lane combining and lane dividing solutions to increase throughput on your production line.

· Alternate Inverting Loop: Discover multiple ways the company inverts containers to create pack patterns and more.

· Twist Blocks: Check out two different mounting options for twist blocks, a backlog driven conveyor accessory that inverts containers.

Quick Changeover Drive Unit Machine with Morrison Auto Adjust Rails®: See the simplicity in timing screw drive unit design and all the upgrades available to improve container handling on your production line. This machine features easy adjust conveyor rails, quick change rails, and down bottle reject guides.

· Change Parts Rotary Base: Attendees can also test their line efficiency skills at the return of the Morrison Changeover Game: Back by popular demand. the Change Parts Rotary Base highlights Morrison’s quick change parts and rotary base design.

“Automation doesn’t have to mean complexity,” said Chris Wilson, President at Morrison. “Our new screw denester and robotic orienting machine are built to simplify how lines operate while giving plants more flexibility, higher speeds, and fewer headaches.”

Additionally, you’ll find Morrison equipment all across the show floor. Many OEMs standardize on Morrison container handling equipment to bring robust container control to their customers. See a variety of Morrison’s products in action at the following Booth locations:

- ELUM Inc. | Booth SL-11075 | Change Parts on the PROTOS labeler

- PDC International | Booth W-3722 | Timing Screws for shrink sleeving

- Spee-Dee Packaging Machinery | Booth W-1916 | Change Parts on fillers

Visit https://morrison-chs.com/about/trade-shows/ to book a meeting, add Morrison to your PACK EXPO show planner.